As devastating as the effects of COVID-19 were on the global economy, the economic slowdown resulted in a 6.4 percent decrease in greenhouse gas emissions. Nevertheless, the planet is still headed toward 3.2°C of warming. The United Nations has found that even 1.5°C will have irreversible, calamitous effects. This means that we will need to find innovative methods for replacing most aspects of our lives.

This includes such overlooked building features as ducting systems and the materials from which they’re made. To address this one aspect of a building’s carbon footprint, architecture group BVN and the University of Technology Sydney (UTS) set about creating a more efficient air ducts for HVAC systems.

While the construction industry is responsible for 40 percent of the world’s CO2 emissions, 33 percent of an office building’s embodied emissions come from services. That can be further broken down to show that 15 percent of the total services footprint comes from redundancy and oversizing. Moreover, because of the materials used, metal ductwork in air conditioning systems makes up 22 percent of the embodied carbon emissions in a building’s services.

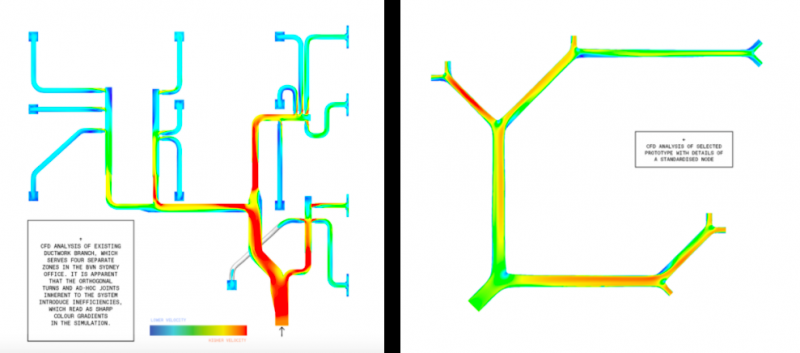

Traditional ducting compared to optimized ducting. Images courtesy of SR2 project.

To replace the steel of which duct systems are typically made, the team used recycled PET plastic waste, cutting the embodied emissions by 90 percent. Additionally, they found that most ducts are laid out in a convenient manner, sacrificing efficiency for what is possible to achieve with conventional manufacturing and installation techniques. This, in turn, resulted in poor airflow.

For this reason, the team 3D printed an organically shaped structure to experiment with airflow in a 100m² portion of BVN’s 2000m² Sydney studio. An industrial robotic arm outfitted with a plastic extruder made it possible to build up organic shapes in midair, eliminating the need for support structures.

The 3D printed ductwork operating in BVN’s studio. Image courtesy of SR2 project.

The resulting Systems Reef 2 (SR2) replaces square corners with aerodynamic curves, as well as large vents with fine pores. Ducting cross sections were cut by 75 percent, while length was reduced by 33 percent and operating energy was dropped by 10 percent. All of the design work featured machine learning for the optimization of components.

The team believes that, if SR2 were installed across the entirety of the studio, it would use 13.21 tonnes of plastic waste to supplant 54 tonnes of traditional ductwork, thus eliminating a megaton of embodied CO2. Due to standardized connections, seals, and fixings, they also think that labor for installation can be cut by 50 percent.

This is just the beginning for the team, which believes it can apply a similar process to other use cases. Additives can easily be incorporated into the material production process in order to improve performance for specific tasks, such as flame retardants necessary for coding.

At the moment, the granulation of recycled plastics takes place in a separate step from 3D printing, but, given past work that Joshua Pearce conducted with Michigan Tech students, one could imagine coupling those two processes for greater efficiency. It would also be interesting to see if energy efficiency could be improved even further in order to warrant the need to replace existing ducting systems because, as it stands, the embodied carbon footprint of the materials used would only be relevant for the production of new ducts. It would be more materially efficient to work with existing ducts than replace them entirely and 10 percent energy savings may not be enough for a government mandate or subsidy for retrofitting office buildings with 3D printed, plastic replacements.