At MIT, a team of researchers has developed a composite material from a synthetic polymer and cellulose nanocrystals. Designed in the form of a gel, it was used to 3D print different shapes, including a tooth, in order to demonstrate the possible future applications of this material. This includes the possibility of producing dental implants with interesting properties when it comes to strength and durability.

Cellulose is a component found in plants, trees and other living species such as algae or bacteria. It is a very abundant natural structure on our planet, which makes it a particularly interesting subject of study for many researchers. Last year, we introduced you to the European project NOVUM which is looking into transforming cellulose into 3D printing material. It would be a greener alternative to petroleum-based products that could have a strong environmental impact on many different industries, including additive manufacturing.

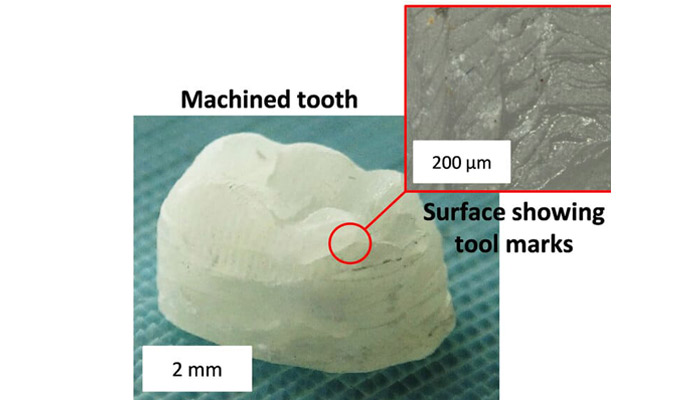

The team succeeded in reproducing the shape of a tooth using this composite material (photo credits: MIT)

The MIT team looked at nanocrystalline cellulose (CNC), which the researchers describe as organic polymer chains arranged in near-perfect crystal patterns that can be extracted from cellulose fibers by acid hydrolysis. These CNCs have unique properties including high strength, thermostability and high chemical reactivity. And just so, the team wanted to build on its strength and understand how they could exploit this abundant material.

They mixed cellulose nanocrystals with a synthetic polymer and found the right ratio between the two to obtain a kind of gel that is easy to extrude via a bioprinter-type machine equipped with a pneumatic extruder. However, the team specifies that the material could be used by molding or machining methods. Nevertheless, they deposited the gel layer by layer to form different parts. One of them was machined to reproduce the structure of a tooth in order to show the usefulness of such a material in the medical sector and more particularly in the production of implants. The hardness of this organic material is comparable to that of aluminum alloys, while its resistance to breakage is similar to that of the cell walls of wood.

Photo Credits: MIT

However, the researchers point out that after extrusion, the composite material dries and the final part shrinks. This shrinkage could be an obstacle in creating larger shapes as it could lead to cracks during this drying phase. So that’s something the team is working on. Abhinav Rao, one of the lead researchers on the project commented, “If you could avoid shrinkage, you could keep scaling up, maybe to the meter scale. Then, if we were to dream big, we could replace a significant fraction of plastics with cellulose composites.” One thing is for sure, the use of this material could reduce the use of petroleum-based plastics and thus have a positive environmental impact for our planet. Find out more about the team’s work HERE.