The hearing aid industry was one of the first sectors to employ 3D printing in mass production of products. Every ear is different, and 3D printing allows perfect bespoke customization for wearers, ensuring a tight and comfortable fit within the ear. In fact, even as far back as 2013, the majority of hearing aids were 3D printed, with over 10,000,000 hearing aids being produced with AM back then.

But prolonged use of in-ear hearing aids can lead to ear infections, which can lead to all manner of issues down the line (speaking from experience with scarred eardrums, a patulous eustachian tube and a ruined scuba diving holiday).

While this writer’s eardrums are doomed, there is still hope for the rapid treatment of ear infections in hearing aid wearers thanks to researchers at the University College London (UCL), who have found a method of embedding antibiotics into the hearing aid itself, which can release the drugs into the ears over a two week period.

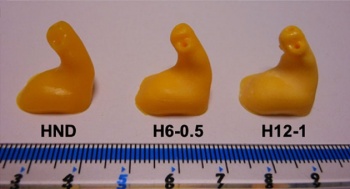

The hearing aids are produced with DLP printing, and have two antibiotics embedded into the structure. The antibiotics are ciprofloxacin and fluocinolone acetonide and the drug-loaded hearing aids have demonstrated anti-biofilm activity against P. aeruginosa and S. aureus.

The devices have proven to be mechanically robust, non-toxic, and have exhibited a hydrophilic surface as well as excellent blood compatibility.

The hearing aids have been produced with two photopolymer resins (ENG hard and Flexible) which are used for their high resolution, high quality surface finish and engineering grade mechanical properties.

How did they load the antibiotics into the resin?

Simple. They mixed the antibiotics directly in with the resins and printed them using a resin-based 3D printer, much the same as any process using photopolymer resins and additives. After printing, the devices are washed to remove any uncured or part-cured polymer remnants before being subjected to a further curing stage under UV lamps.

The mechanical properties of the hearing aids were unaffected by the addition of the antibiotics, and the hearing aids themselves demonstrated drug release for more than two weeks inhibiting biofilm formation on the surface of the hearing aids mitigating bacterial growth in the surrounding medium (the ear).

The research opens the way for future applications of 3D printed patient-specific medical devices with anti-bacterial properties such as cochlear implants and other devices that may be subject to causing infection.

The research paper titled: ‘Anti-biofilm multi drug-loaded 3D printed hearing aids’ will be published in the Materials Science and Engineering journal volume 119, February 2021.