A while ago, in 2020, Spanish company BCN3D and the German Henkel group joined forces for a long-term partnership. Recently, it has been announced that the collaboration will now focus on developing formulations for the recently launched Viscous Lithography Manufacturing (VLM) 3D printing technology. Henkel, which is particularly known for providing end-to-end engineering solutions within additive manufacturing, is playing a major role when it comes to the new materials for VLM and is helping BCN3D achieve its goal of accelerated manufacturing autonomy.

The long-term goal of both sides in this partnership of manufacturers is supposed to be to ensure full control over every stage of the production process within additive manufacturing. To make that a reality, the special properties of VLM will be used to generate new and innovative solutions for high-performance resins.

VLM has many new benefits in additive manufacturing (photo: BCN3D/Henkel)

What Kind of Technology is VLM?

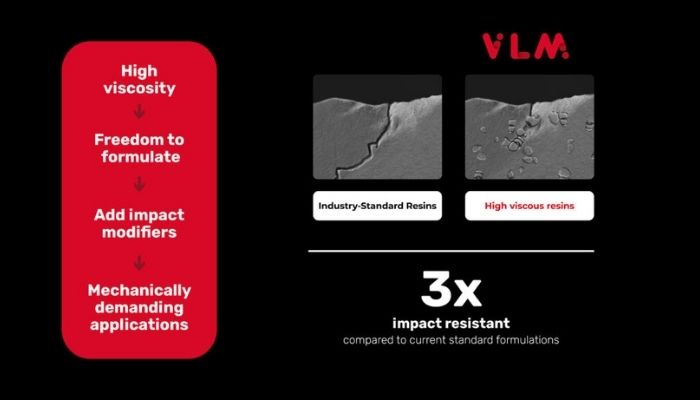

Viscous Lithography Manufacturing is a lithography-based 3D printing process, in which thin layers of highly viscous resins are laminated onto a transparent transfer film. This allows high-performance components to be produced in a fast and cost-effective process. The main difference to existing resin technologies in additive manufacturing is that VLM is capable of using resins that are 50 times more viscous than the industrial standard resins are today. This can also be traced back to the latest modifications of constraints. New ingredients can now be added to the resin to achieve the desired changes in thermal and mechanical properties.

Sam Bail, Director of 3D Printing & Partnerships at Henkel is visibly pleased with the joint achievement in additive manufacturing: “BCN3D has unveiled a groundbreaking technology that enables printing high viscosity resins. Thermal & mechanical properties are enhanced by additives that typically increase the viscosity of the resins, which in other cases makes them more difficult to print. The BCN3D team has developed a novel technology that removes the limitations of viscosity and allows the printing of a wide range of new materials which we have witnessed firsthand over the last few years of collaboration. We look forward to seeing the tremendous impact VLM technology brings to the additive market together with new Henkel Industrial resins.”

Henkel’s resins, made for 3D printing, will then be used at BCN3D’s new application center, where the VLM Technology Adoption Program will also take place. By also being used by other companies, the full potential of VLM technology will be revealed as soon as 3D printing parts are created.

“BCN3D is very excited to announce this collaboration with Henkel, and it represents a significant milestone in the history of VLM. The VLM Technology Adoption Program is showing us the potential of VLM technology and how it can help companies to overcome their current limitations. There is no doubt that this technology combined with new customer-targeted formulations will fulfill the needs of the AM sector.” Xavier Martínez Faneca, CEO of BCN3D, confirmed in a press release. You can find out more on

*Cover Photo Credits: BCN3D/Henkel