Chinese manufacturer Flashforge has announced the launch of a new professional FDM 3D printer, the Guider 3. Designed for the production needs of small and medium-sized businesses, the machine is fast, with a compact and lightweight design to ensure flexible and efficient production. The Guider 3 is part of the manufacturer’s Guider line of professional, industry-focused machines. It joins the Guider 3 Plus, a fast and quiet 3D printer compatible with a wide range of thermoplastics.

In June, Flashforge introduced the Guider 3 Plus, a solution designed for rapid prototyping of large-scale models such as architectural models, figurines and movie props. The printer is notable due to its high printing speed all while maintaining a high level of accuracy. However, it wasn’t long before Flashforge launched a new product, this time aimed at digital production for small and medium-sized businesses. The Guider 3 has been designed to meet production needs: but what exactly are its features? And what can we expect from this new professional machine?

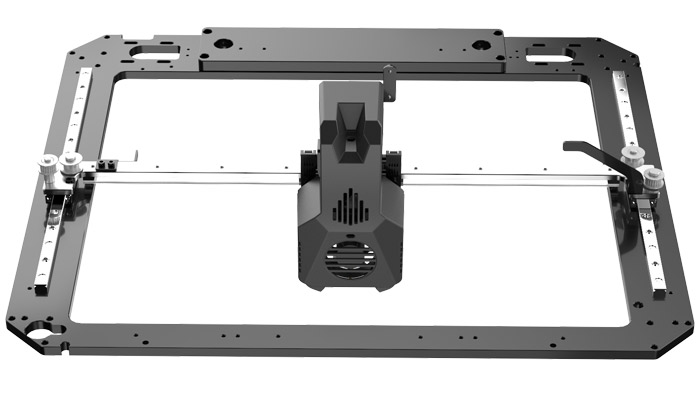

The Guider 3 is equipped with a coreXY system that allows for a high printing speed (photo credits: Flashforge)

The Main Features of the Guider 3

With a coreXY structure that supports a maximum print speed of 250mm per second, the Guider 3 has a print volume of 300*250*340mm. It offers a complete workflow for professionals with limited budget and working environment. The printer is compact and incorporates a real-time monitoring system, resuming printing in the case of power outages, thus ensuring stable and continuous printing 24 hours a day.

In terms of hardware, the Guider 3’s structure is aluminum, with an outer shell made from durable and lightweight ABS and acrylic sheets. The machine is indeed 20% lighter compared to the previous generation of Flashforge 3D printers. Its printing plate is made of glass, but users can easily change to a flexible steel plate to suit their needs. They will also be able to rely on an automatic leveling of the printer bed which has been optimized by the Chinese manufacturer. It has integrated an inductive proximity sensor that checks that the bed is as flat as possible, records the data and compensates for the height of the plate in terms of the Z axis during printing.

Finally, the Guider 3 is compatible with a wide range of thermoplastics thanks to an open system. Equipped with a double gear extruder, the filament feed force is increased by 150% and the risk of nozzle clogging is reduced. The extrusion temperature can reach 320°C. As such, Users will not only be able to use standard filaments such as PLA and ABS, but also PETG, PA, PC, ASA and HIPS.

Flashforge 3D printers meet a variety of needs (photo credits: Flashforge)

Flashforge Enters the Professional Market

All of these features demonstrate Flashforge’s commitment to offering a reliable and durable solution that remains accessible and easy to use. Flashforge thus confirms its intention to move into the professional 3D printing market, whether for prototyping needs or small and medium series production. The company’s range of products currently covers all these needs and addresses a variety of sectors. Take, for example, its Creator 4 range, designed for a wide array of high-performance end-use applications in multiple industries such as automotive, medical and consumer goods. With the Guider 3 launch, the Guider 3 series now fulfills rapid prototyping and small-batch production demands.

If you would like to know more about the new Guider 3 machine from Flashforge, please click HERE. Additionally, if you need a custom solution for your digital production project, feel free to contact Flashforge’s team. They will suggest the best printer based on your demands and budget.

*Cover Photo Credits: Flashforge