Top companies in 3D printing schedule their new product launches to coincide with the industry's largest trade show, Formnext. Although the show this year is virtual, the new products and innovations are very real!

Every November for the past five years, the additive manufacturing industry has showcased the latest innovations at the Formnext trade show in Frankfurt, Germany. Nearly 800 exhibitors – from 3D printer manufacturers to service providers to material and software developers – were expected to converge for four days of showing off their latest products and programs to thousands of visitors. The global pandemic halted the in-person trade show, but not the new products that exhibitors are still debuting this week during Formnext Connect, the virtual trade show.

If you’re disoriented trying to navigate the virtual Formnext for the latest products, don’t worry, we’ve got you covered. Below, we’ve collected some of the major new announcements. Our list will be updated with each day of the trade show until Nov. 13, so be sure to check back.

NEW PRINTERS & HARDWARE

Ultimaker: 2+ Connect Printer For Print Labs

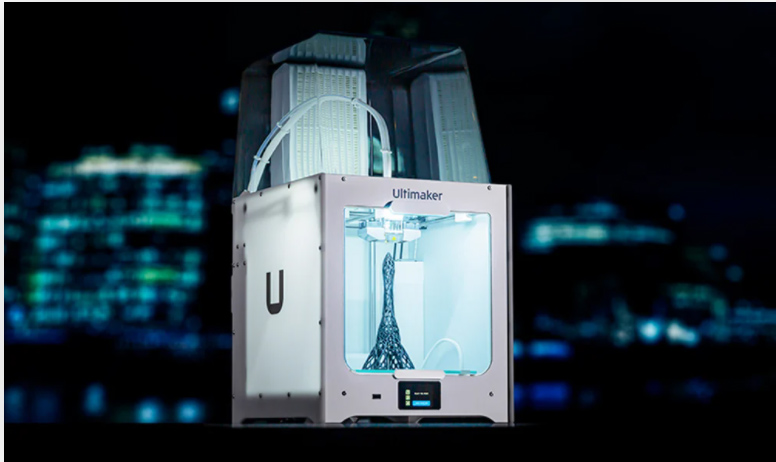

Ultimaker 2+ Connect and Air Manager (Source: Ultimaker)

Ultimaker introduced the Ultimaker 2+ Connect, a single extrusion 3D printer, designed for 3D printing labs in higher education and small enterprises, the company says. Focusing on ease-of-use, safety, and connectivity, the “connect” in the 2+ Connect refers to cloud 3D printing through the Ultimaker Digital Factory, which enables remote file transfer with added security from anywhere globally and simplifies the installation of multiple machines.

Ultimaker says this model can expand student access to additive technology and help businesses save time and cost compared to outsourcing by printing prototypes with a wide choice of inexpensive materials. The printer offers intuitive control via its 2.4-inch color touchscreen, an ergonomic feeder lever, and a stiffer build platform, reinforcing ease of use and reliability.

Every Ultimaker 2+ Connect comes with free e-learning as part of the Ultimaker 3D Printing Academy. Created by Ultimaker’s experts, the course guides users through setup, maintenance, use of Ultimaker Cura, and more.

The Ultimaker 2+ Connect features a 0.4 mm nozzle, which the user can swap for a 0.25 mm for detailed prints, 0.6 mm for faster prints, or 0.8 mm for quick drafts or 3D sketches.

Also new is the optional Ultimaker 2+ Connect Air Manager, a top cover and front enclosure combination proven to remove up to 95% of ultrafine particles, and shields users from hot and moving components.

PRICING AND AVAILABILITY

The Ultimaker 2+ Connect costs $2.499 and is available immediately through Ultimaker’s global partners’ network. The optional Ultimaker 2+ Connect Air Manager costs $450.

Smart3D: The High-Temperature Macro HT

Smart3D, the Argentinean 3D printer manufacturer better known for making printers under the Kodak brand, just launched a high-temperature version of its Macro 3D printer called the Macro HT.

The Macro HT’s 200 °C chamber can handle high-performance materials including PEEK, PEEK CF, ULTEM1010, PPSU, and other third-party filaments.

The printer also features a beltless motion system, using ball screws for XY motion. This leads to improved accuracy and significantly reduced downtime, with less wear and tear and a reduction in regular maintenance, the company says. The Macro HT is production ready, enabling companies to transition from product development with Smart3D’s prototyping units to manufacturing with a shared hardware, software, and material platform.

The Macro HT uses the company’s Smart3D Cloud, with the option to install the Smart3D LAN printer management software locally. The company’s solution for the production floor is Smart3D Serverless, a decentralized neural network to provide safe connections with unbeatable redundancy. The Factory Management module offers multiple packages to integrate Smart3D systems with the factory’s full workflow.

PRICING AND AVAILABILITY

The Macro HT will be available in Dec. 2020. Price: Not disclosed.

atum3D: Orthotics Resin Printer, Vacuum Post-Curing Unit

atum3D, the Dutch resin printer manufacturer, launched the DLP Station 5-365 EXZ featuring a large build volume (190 x 107 x 450 mm) and open resin platform.

The high-resolution DLP Station 5-365 EXZ is designed as a solution for on-site printing of client-specific orthotics and orthopaedics. “We believe this printer hits a sweet spot in terms of versatility, speed, accuracy, material properties, and cost-effectiveness,” the company says.

atum3D also debuted its new Curing Station, a vacuum post-curing solution with fully customizable presets that allow combining the vacuum, pressure, UV light dose, degas time, and the cool-down time for a series of subsequent steps, which can be saved in a curing preset.

PRICING AND AVAILABILITY

The DLP Station 5-365 EXZ’s technical details are available on atum3D’s website but availability is not specifically mentioned. Price: Not disclosed.

Solukon: Powder Removal, Cleaning Machine for SLS Parts

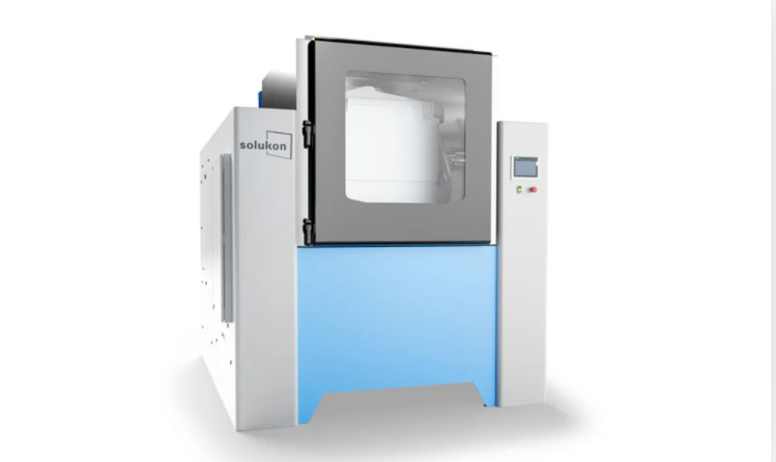

The SFP770 fully automated system for unpacking and cleaning SLS parts (Source: Solukon)

Solukon Maschinenbau, the German manufacturer of automated postprocessing systems for additive manufacturing, introduces a machine that fully automates unpacking and cleaning laser sintered polymer parts. The SFP770 accommodates the entire build box from the EOS P7 printer, removes the powder in minutes and collects it for recycling, then automatically transfers the parts to a rotating cleaning basket where they are shot-blasted with glass beads and ionized air.

Solukon says the SFP770 offers the shortest unpacking time available without manual intermediate steps.

PRICING AND AVAILABILITY

Available now. Price: Not disclosed.

Mimaki: Full-Color Prints, Compact Printer

Japanese manufacturer Mimaki unveiled its newest full color 3D printer, the 3DUJ-2207, which is a smaller version of its industrial counterpart that brought over 10 million colors to the 3D printing market. The new printer aims to extend the reach and accessibility of Mimaki’s resin-based technology to a new segment of customers with a printer priced under $45,000.

The 3DUJ-2207’s compact design and 203 x 203 x 76 mm build space makes it ideally suited for office environments, the company says. The printer is ideal for medical models, prototyping, as well as art and education applications – all within a machine sufficiently compact to fit in an office elevator.

“Utilising UV-curing inkjet technology, the expansive high-definition colour expression made possible with the Mimaki 3DUJ-2207 3D printer is around twice that of powder bed manufacturing methods,” the company says. “This provides new possibilities for prototyping and enables the accurate reproduction of subtle color differences which are critical for many industrial design applications such as medical and architectural modeling.”

PRICING AND AVAILABILITY

The 3DUJ-2207 is expected to be available by April 2021. Price: under $45,000.

Wematter: Improved, Easier-to-Use SLS Printer

Robert Kniola with prints from Wematter Gravity SLS 3D-printer 2021 (Source: Wematter)

Swedish 3D printer and materials manufacturer, Wematter, launched a new thermoplastic selective laser sintering 3D printer, the Gravity 2021 that boasts improved software, better recoater mechanics, and higher overall ease of use compared to its original Gravity printer. The company says the new machine provides a smoother sintering process with the help of its software’s new algorithms.

“Many of our competitors let the user control the process parameters of the machine, forcing customers to hire pure operators,” says founder and CEO Robert Kniola. “We want to change that! One hour of training should be enough for anyone to be able to print, regardless of previous experience.”

In connection with the launch of Gravity 2021, Wematter also debuted its Density 2021, a new model of its popular water-jet cleaning cabinet with improved ergonomics.

PRICING AND AVAILABILITY

Price and availability have not been disclosed.

Titan Robotics: Huge Filament 3D Printer with Pellet Capacity

Atlas 3.6 3D printer (Source: Titian Robotics)

Titan Robotics, the American manufacturer of large-format 3D printers specializing in direct pellet-fed 3D printing, introduces its Atlas 3.6 with a build volume of 1270 x 1270 x 1828 mm. Atlas 3.6 is one of the largest plastic pellet extrusion 3D printers on the market and features a heated enclosure enabling customers to print large parts with high-performance materials, including CF-PEI, GF-PEKK, nylons, and ABS.

With several extrusion configuration options, including Dual Pellet and Hybrid Pellet + Filament, the Atlas 3.6 provides solutions across a wide range of applications, including large-format tooling, patterns and molds, and functional parts, the company says.

PRICING AND AVAILABILITY

The Atlas 3.6 is available now. Price: not disclosed.

Optomec: 3D Printer Tech for Metal Part & Repair

The CS250 and the HC-TBR directed energy deposition 3D printers (Source: Optomec)

Optomec, the American manufacturer of 3D printers specializing in directed energy deposition technology often used for metal part repair, launched two printers this week: the CS250 and the HC-TBR.

Both are designed around a 250 x 250 x 250 mm build volume suitable for small part production and repair, including batch processing. The systems also feature a print head capable of automatically changing the laser spot size and output power on the fly, “so they can apply material faster to larger areas of the part yet still create fine features with lower heat input to thinner areas of the build,” the company says. These printers have an optional processing capability for printing reflective and reactive alloys, such as copper, aluminum and titanium, in addition to a wide variety of other common metals including steels and nickels.

The CS250 machine, designed for research, is an all-in-one system with up to four integrated powder feeders, enabling rapid alloy development and graded-material part creation. The HC-TBR machine is designed for high-performance, high-volume production applications with the capability of automatically moving and processing titanium parts into and out of an inert atmosphere.

PRICING AND AVAILABILITY

The CS250 is priced below $300,000. Availability not released.

Farsoon: SLS Powder Management System, Cooling Station

SLS powder management system and cooling station (Source: Farsoon)

Chinese manufacturer of SLS printers, Farsoon, announced a polymer powder management system and an external cooling station for plastic part production that aim to speed up large-scale additive manufacturing by enabling a clean and safe production environment without direct contact of operators with powder.

Farsoon’s powder management system features used powder recycling and storage, new powder supply, and high-speed mixing and sieving. The system can also be paired with a mobile powder delivery unit, which transports the prepared powder directly to the printers.

The Farsoon 403P series external cooling station reduces part cooling time and is designed for cooling the build cartridge part cake without the need for long cool down time inside the main system. The external cooling process is protected under a controlled inert gas atmosphere for uniform cooling.

Bother machines are in a pilot program with WeNext, a Chinese rapid prototyping service provider, but the company is actively seeking other pilot program partners.

SLM Solutions: Industrial Metal 3D Printer Designed for Mass Production

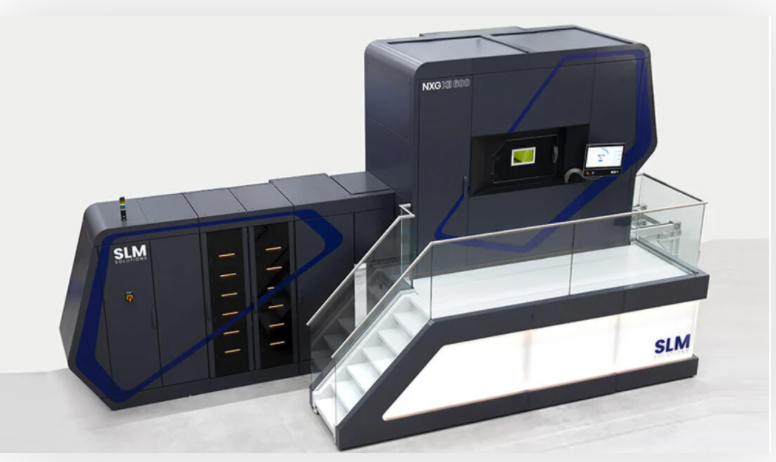

The large-format NXG XII 600 metal 3D printer (Source: SLM Solutions)

Germany-based SLM Solutions launches its new large-format NXG XII 600 metal 3D printer designed for serial production and printing large parts. The printer features 12 lasers with 1 KW each and a square build envelope of 600 x 600 x 600 mm.

SLM Solutions says the NXG XII 600 is 20 times faster than the company’s single-laser machine. To facilitate the integration of the NXG XII 600 into factories and supply chains, several features, including an automatic build cylinder exchange, automatic build start and an external preheating station and external depowder station are part of the solution.

The machine is available with two powder handling options: a gravity based and a vacuum based solution, that both keep downtime between each build job to a minimum, the company says.

NEW MATERIALS

Essentium: EDS-Safe Filament in Red

Essentium, the American printer and material manufacturer, introduced an electrostatic discharge (ESD) safe and anti-static thermoplastic polyurethane filament that is available for the first time in color. Unlike other ESD-safe materials that are only offered in black due to carbon additives, the new Essentium TPU 58D-AS is red. Targeting applications, such as space vehicles and satellite manufacturing, where no-fly parts must be both ESD safe and red in color, Essentium says its new filament has a high impact and tear strength, excellent abrasion resistance, and is safe for cleanroom and electronics manufacturing applications.

In addition to Essentium TPU 58D-AS, the company introduced two new high-performance, heat-resistant materials to expand the open ecosystem of industrial-scale additive manufacturing solutions: Essentium PET-CF, which is a 15% carbon fiber reinforced polyester filament made with Luvocom 3F resin from Lehvoss; and Essentium 9085, which is made with SABIC’s ULTEM™ 9085 resin offering high heat resistance and mechanical strength for aerospace, automotive, oil and gas, electronic manufacturing, and tooling applications.

PRICING AND AVAILABILITY

Essentium TPU 58D-AS is available now at $82,50 for 750 grams.

Fehrmann Alloys: New Aluminium Alloy Powder

(Source: Fehrmann ALLOYS)

German material manufacturer, Fehrmann Alloys unveiled its new high-performance aluminium alloy metal powder for 3D printing. The AlMgty-90 is an aluminium alloy at a similar level of AlSi10Mg and a density of 99%.

The company says the new material will enable increased productivity for metal additive manufacturing with a considerable reduction of material cost and production time.

AlMgty-90 features all the attributes of high-performance aluminum powers, including corrosion resistance, polishable, weldable, and a particle size range of 20-70 microns. AlMgty 90 boasts a tensile strength >400 MPa and an elongation at break >25%.

A full technical spec sheet is available here.

PRICING AND AVAILABILITY

AlMgty 90 is available now. Price: not disclosed

Nexa3D: All-Purpose & Casting Resins

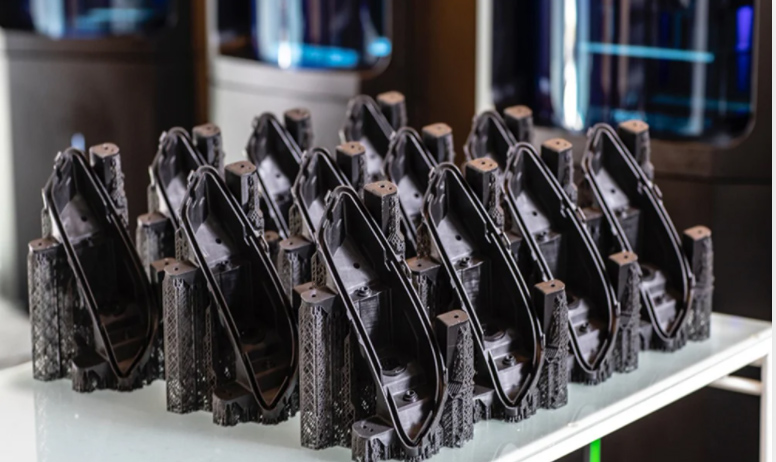

Parts with xPRO410 resin (Source: Nexa3D)

Nexa3D, the American maker of resin 3D printers and materials, introduced a general purpose photopolymer resin called xPRO410, along with a material designed for metal investment casting patterns called xCast. Both resins are optimized for printing on Nexa3D’s NXE400 SLA 3D printer.

Chemical company Henkel partnered with Nexa3D to develop the xPRO410 resin, which is formulated based on Henkel’s LoctitePRO410 polymer.

xCast is a more economical and scalable alternative to other direct and indirect metal 3D printing solutions, the company says, and features a cleaner burnout for a variety of metals, including titanium and aluminum alloys, faster pattern printing and draining for a variety of sizes.

PRICING AND AVAILABILITY

xPRO410 is available now. Price: not disclosed.

Tiger Coatings: Flame-Retardant SLS Powder

Parts made from TIGITAL 3D-Set PPP 371 thermoset powder on the Farsoon HT252P platform (Source: Farsoon)

Germany-based international material manufacturer TIGER Coatings teamed up with 3D printer maker Farsoon to launch a flam retardant plastic powder for selective laser sintering. The material, TIGITAL 3D-Set PPP 371, produces end-use functional parts for automotive, electronics, transportation, and aerospace industries with excellent thermal and mechanical performance, the company says, along with good electronic isolation and chemical resistance.

The material was developed for the Farsoon SLS printer HT252P, which is an open-material SLS machine.

NEW SOFTWARE & SERVICES

Interspectral: AM Explorer Visualization Software for Metal 3D Printing

Designed specifically for users working with layer-based metal additive manufacturing, AM Explorer makes it possible to fuse, explore, and analyze design files, simulation data, machine monitoring data, and post-build metrology data from the metal additive manufacturing process. The software enables manufacturers to more easily understand process data and thereby reduce manufacturing costs, improve quality, and accelerate the application development.

The Swedish developer Interspectral initially developed the software for Siemens Energy, one of the world’s leaders in designing and producing commercial AM components for serial production and has one of the largest metal AM printer fleets in the world.

After more than a year in development, AM Explorer is now available to the broader additive manufacturing market.

“The first step in enabling far-reaching intricate designs and further pushing the possibilities of additive manufacturing is to see and understand what really has been printed,” says Andreas Graichen, group manager in the AM Center of Competence at Siemens Energy in Finspång, Sweden.

AM Explorer is machine and data agnostic and is easily plugged into existing systems meaning that basically any organization working with metal 3D printing, can be up and running analyzing their data in minutes, the company says.

PRICING AND AVAILABILITY

The software is available now, but the price was not disclosed.

Desktop Metal: Simulation Software to Detect, Fix Part Errors

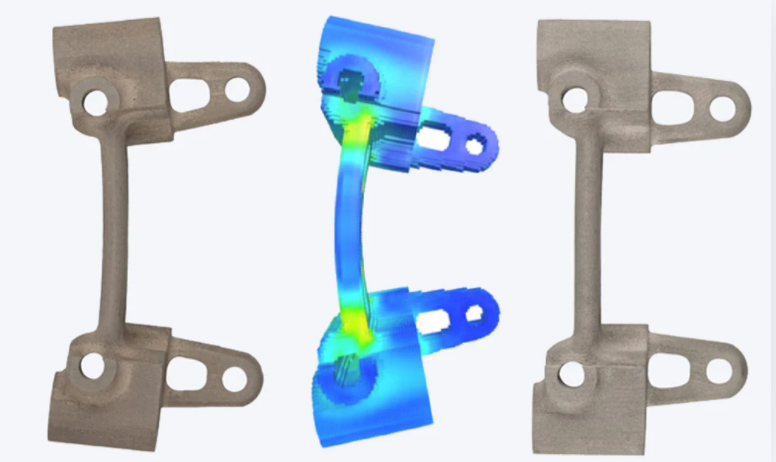

Live Sinter software (Source: Desktop Metal)

American printer manufacturer, Desktop Metal, launched a software solution designed to eliminate the trial and error required to achieve high-accuracy parts during the metal 3D printing processes. The software, Live Sinter, can correct part files for shrinkage and distortion while also diminishing or eliminating the need for sintering supports.

“Live Sinter offers additive manufacturing engineers fast and predictable sintering outcomes, with simulations results in as little as five minutes and negative offset geometries in as few as twenty minutes,” the company ways.

The software application not only corrects for the shrinkage and distortion of parts typically experienced during sintering, but also opens the door to printing geometries that, without the software, would present significant challenges to sinter, the company says. “By improving the shape and dimensional tolerances of sintered parts, first-time part success for complex geometries is improved and the cost and time associated with post-processing are minimized.”

AVAILABILITY AND PRICE

The software is initially only available with the company’s Shop System, starting in late 2020, and Production System, in 2021. Price: Bundled with Desktop Metal binder jetting technology.