It’s Olympics time in Japan, and that means it’s time for sports equipment manufacturers to show off their wares to the sports-spectating public at large.

Last week we had a little chat with Dimitris Katsanis, Founder and CEO at Metron A. E. Ltd, who are based in Nottingham U.K.

Metron A.E (“Additive Engineering”) specializes in metal forming, and have been providing a variety of domains with design and manufacturing services and products over the years. One domain in particular has been benefiting a lot from the work at Metron A.E, and that is the cycling domain.

Last week Katsanis posted some pictures of their metal printed racing bicycle handlebars, which will feature in the Olympics over the next few weeks in Japan.

Let’s have a look at what’s up with those handlebars. As you can see, the handlebars below are an assembly, rather than a single part.

Titanium and Scalmalloy assembly (Image credit: Metron A.E)

What is interesting is the choice of metals used in this assembly. The main bar piece in the picture (the darker piece) is made from 3D printed titanium (Ti6Al4V) and the extensions (the lighter, longer parts) are printed with Scalmalloy.

What is Scalmalloy?

“Scalmalloy is the strongest aluminium alloy available for 3D printing that is backed by an extensive material database,” said Katsanis.

“Both Ti6Al4V and Scalmalloy can produce strong and lightweight components, but in this case, Scalmalloy had the edge; because of its lower density, some sections could be made using less material, resulting in lighter overall components.”

Indeed. Scalmalloy (scandium (SC), aluminum (AL) and magnesium (M) alloy (ALLOY)) benefits from significant gains in material strength simply by addition of a tiny amount of scandium to the alloy. It is a great material, and was developed by Airbus specifically for metal additive manufacturing. The high specific strength of the material makes it beneficial to aerospace and high level professional cyclists also.

What printers did they use to print these parts?

“In this particular case, the base bars are made using Ti6Al4V on our ARCAM EBM and the extensions are made using Scalmalloy on our EOS M400,” said Katsanis.

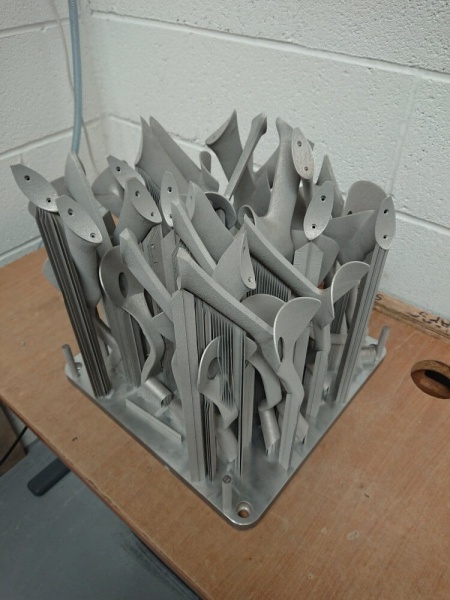

You can see the handlebar extensions still attached to the baseplate in the image below.

Scalmalloy bar extensions printed on EOS M400 (Image credit: Metron A.E)

Scalmalloy bar extensions printed on EOS M400 (Image credit: Metron A.E)

Metron has had plenty of experience to draw from in this latest handleebar design, as they have been manufacturing pro cyclist equipment for a few years now. In fact, Metron’s products have helped cyclists win over 200 world metals in the sport.

Finished assemblies (Image credit: Metron A.E)

Finished assemblies (Image credit: Metron A.E)

One such record has been achieved by cyclist Cameron Wurf, a triathlete that holds the record for the fastest cycling segment in the Kona Ironman triathlon. Wurf used an earlier iteration of the aerodynamic bars, fabricated entirely out of AM titanium, as you can see in the image below.

This bar assembly is titanium only (Image credit: Metron A.E)

The newest bars (the Scalmalloy/titanium ones pictured in this article) will be used by the Italian national team for track events in the Japan Olympics.

The British and Southeast Asian teams have received 9 sets of a different design from Metron, and a further 10 sets of another have gone to riders of various nationalities in the road TT event.

So all in all, there is a lot of 3D printed metal in this year’s Olympic cycling events, and no doubt Metron will see a few more medals secured with their latest designs.