A recently developed ventilator has been unveiled by a team of researchers from Hungary, and they hope that the modular system, which has been designed with the aid of additive manufacturing, will aid in the ongoing battle against COVID-19.

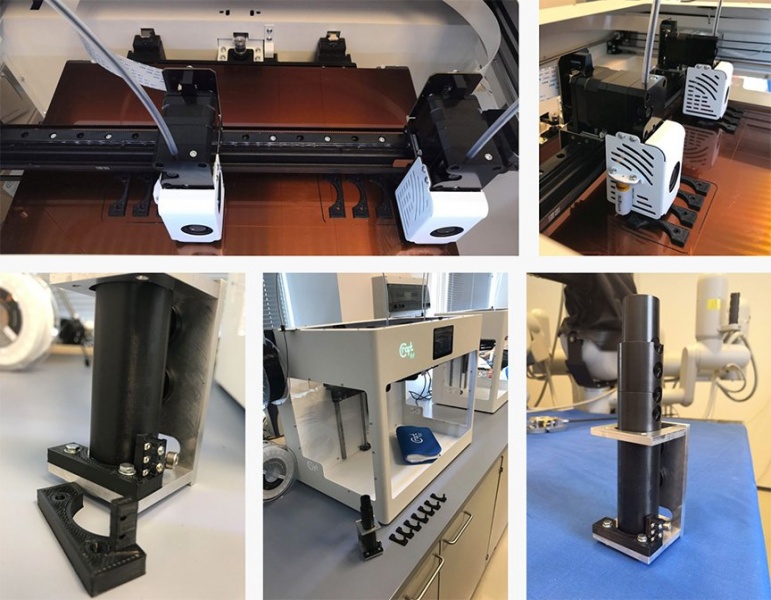

The mass ventilator on test on the patient lung simulators. (Image credit: University of Óbuda)

With the aid of local 3D printer manufacturer Craftbot (headquartered in Budapest) and support from the European Commission, the team has put together a modular ventilator system for use in emergencies, should the supply of specialist, clinical ventilators run short.

Craftbot have had prior experience in the 3D printing of dental and orthopedic supplies in the past, and so with this experience they were the ideal local partner for the researchers from the University of Óbuda, which is a technical university, also located in Budapest.

The MassVentil project is a modular mass ventilator system, which in the event of critical circumstances can be used to ventilate 5 patients at the same time. The team hopes their system will be capable of ventilating up to 50 patients in future. In addition to this feature, the MassVentil system does not require to be hooked up to hospital infrastructure for gas and electric supply. It can be used as a stand-alone device, giving the solution the benefit of mobility which may be needed in temporary hospital facilities.

With the help of the two 3D printers donated by Craftbot, the team were able to bring their design to life and have it tested in a laboratory setting within a few months.

“The system also protects the healthcare professionals by transporting the contaminated exhaled air from the common hospital space, unlike currently used ventilators,” said Dr. Miklós Kozlovszky, head of the project at the university.

Hardware

The printers that were provided by Craftbot were the Craftbot FLOW and Craftbot FLOW IDEX models which are FFF-type printers.

The baseline FLOW has a single extruder and fairly large build volume of 300 x 200 x 250 mm, while the FLOW IDEX comes with dual extruders and a larger build volume of 425 x 250 x 250 mm. All of the Craftbot printers are capable of printing a range of polymers including PLA, ABS, HIPS, PET and Nylon.

The researchers at the university used the printers for the fabrication of their prototypes, as you can see in the image below.

Craftbot for working on ventilator parts (Image credit: University of Óbuda)

As we have seen in other AM-based solutions over the last year, this recent project additionally highlights the utility of additive manufacturing during the pandemic.

“The MassVentil Project could save the lives of thousands worldwide during times of pandemic causing acute respiratory problems, like the current COVID-19” – said Kozlovszky.

While the innovation has come due to the emergence of COVID-19, the MassVentil project can be used for other respiratory ailments such as MERS and SARS. The project therefore has application in the post-COVID-19 world as well as in the short term and is therefore an ongoing project.

We will keep you updated for any changes to the project as it progresses.