Researchers from the I-Form Advanced Manufacturing Research Centre in Dublin have published a study investigating the effects of metal powder reuse on the porosity of 3D printed parts. The team employed X-ray tomography, AFM (atomic force microscopy) roughness measurements, and nanoindentation measurements with the aim of determining the optimum number of reuse cycles for stainless steel 316L powder.

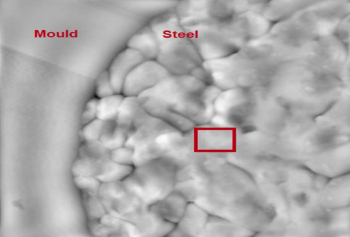

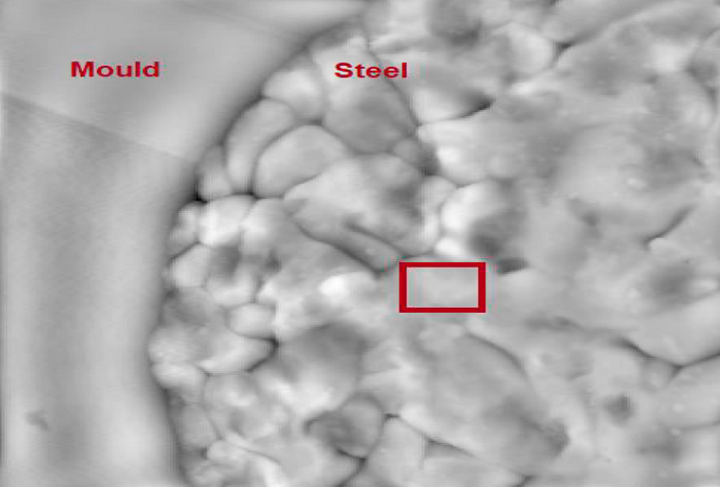

XCT imaging measuring the porosity distribution and concentration. Image via I-Form Research Centre.

The problem with powder reuse

Additive manufacturing companies reuse powder after a print job to cut down on waste and save in material costs. This does come with challenges, however, as most powders are at risk of surface oxidation, clustering, and porosity formations – all of which affect the mechanical properties of the final 3D printed parts in a detrimental way. When looking at stainless steel 316L in particular, it is the increase in the number of porous particles and the level of oxidation that pose the greatest risks.

Certain critical applications in industries like medical and aerospace will only ever use fresh powder as the financial risk and threat to human life is simply too great. For a recycled powder to be used, it would need to produce parts with mechanical properties indistinguishable to that of fresh powder parts. The process of sieving does a good job of removing clumps but does nothing for the abundance of porous particles and their surface oxidation.

Characterizing stainless steel 316L

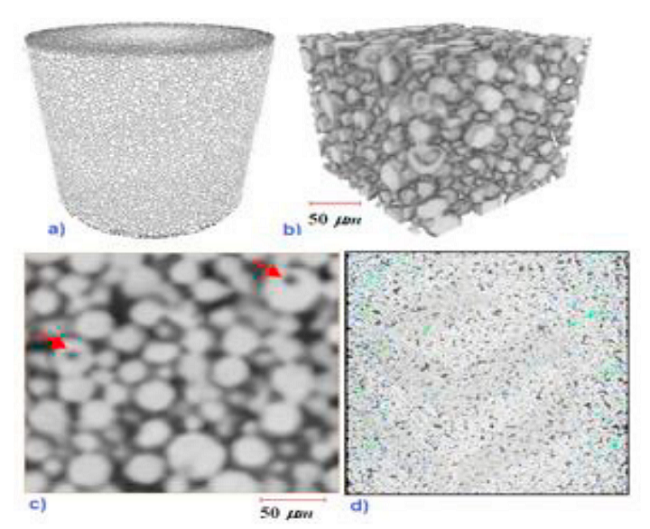

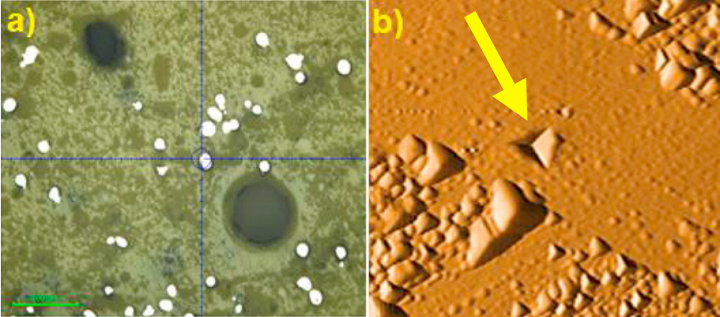

The first portion of the experiment involved printing nine sample cubes (5 x 5 x 5mm) on an EOSINT M 280 metal 3D printer. The team extracted the leftover powder after the print and sieved it to remove clusters. Both powder groups were analyzed using X-ray computing tomography and nanoindentation. The surface roughness of the powders was also measured using AFM. The nanoindentation tests were intended to determine how much of an impact porosity actually has on the hardness and effective modulus of a powder sample while the XCT imaging gave insight into the distribution, size, and concentration of the porosities in the powder.

The nanoindentation test. Image via I-Form Research Centre.

The analysis revealed a more than significant 10% increase in porosity in the recycled powder when compared to the virgin powder. The 3D printing process also increased the roughness of the powder surfaces by around 28%. On top of this, the recycling reduced the hardness from 237GPa to 207GPa and reduced the effective modulus from 9.87GPa to 9.6GPa. The research team attributed the deterioration in mechanical properties to the increase in porosity created under the surface.

AFM imaging measuring surface roughness. Image via I-Form Research Centre.

Further details of the study can be found in the study titled ‘X-ray Tomography, AFM and Nanoindentation Measurements for Recyclability Analysis of 316L Powders in 3D Printing Process’. It is co-authored by Nima Gorji, Robert O’Conner, and Dermot Brabazon.

Earlier this year, a similar study was conducted by the University of Washington focusing on the effects of Ti6Al4V powder reuse on 3D printed part quality. The researchers found that the commercially-available grade 5 Titanium alloy had a significant drop in morphological and surface quality as the number of reuse cycles increased. Elsewhere, researchers from Lawrence Livermore National Laboratory have discovered a way of reducing defects in metal 3D printed parts by carefully controlling the spatter launched out the melt track.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows metal alloy powder. Photo via PyroGenesis.