One of the fields where 3D printing is gaining great popularity is dentistry. 3D printing in the dental sector is a tool that allows the creation of parts adapted to the needs and morphology of each patient. Whether it is through the use of resin additive manufacturing or powder bed fusion, this production method opens up a wide range of possibilities for professionals in dental clinics and laboratories. In addition, dental 3D printing often goes hand in hand with other digital solutions, such as new CAD tools or dental 3D scanners used to capture the patient’s dental anatomy. In short, this ecosystem of new technologies brings a wide range of benefits to dentistry. But what are the real uses we can highlight in this field, what technologies are being integrated and for what purpose? In this list we present the main applications of 3D printing and other technologies in the dental sector.

3D Scanning in The Dental Sector

Although this is not a dental 3D printing application per se, we couldn’t pass up mentioning 3D scanning. The use of 3D scanners is becoming increasingly common when it comes to 3D printing and dentistry. In fact, it is one of the first steps in the digital workflow. Thanks to 3D scanners, health professional are able to digitize the inside of the patient’s mouth if they use an intraoral scanner, or digitize the impressions via a laboratory scanner. This second solution is used in additive manufacturing. A digital file of the impression is created and can be exported in STL format for 3D printing. That’s the how, but what about why? One of the advantages of using a 3D dental scanner is the precision obtained. It also gives the possibility of producing custom-made devices, based on the exact morphology of the patient. Moreover, if the patient needs an emergency prosthesis, for example, there is no need to make new impressions since these have been digitized. The patient saves time, as does the health professional.

Photo credits: 3Shape

Crowns and Bridges

Dental crowns and bridges are some of the most common dental treatments as they are used to replace missing teeth. They are similar in many ways but the essential difference between the two is that dental crowns are used to cap a damaged or decaying tooth, placing it on top of the damage. They can also cap dental implants in the case of there being no tooth left. Meanwhile, bridges are used to replace missing teeth, consisting of two crowns (one on either end) and then a bridge of dentures as needed. And of course, 3D printing is increasingly playing a role in dentistry. Temporary, highly accurate, aesthetic 3D printed crowns and bridges can be made using resin 3D printing. The technology is becoming increasingly popular because it allows for more cost-effective and faster production than the traditional milling processes. Though currently, 3D printed crowns and bridges are mostly temporary as the dental resins are not as durable as zirconia, the technology is continually advancing making it likely that this will change in the near future.

Photo credit: Formlabs

Aligners and Retainers

More and more dental devices are being produced by additive manufacturing, but it has not only allowed a greater manufacturing speed but also greater customization, a very important aspect in this sector as each mouth is different. Now we will talk about retainers or “aligners,” devices used to prevent or even move patients’ teeth. To produce them, the process begins with a scan of the patient’s mouth, then CAD software is used and once we have the file we export it to the 3D printer we are going to use. The most commonly used technology is resin 3D printing such as (SLA), (DLP) or (MSLA). Depending on your needs, you will use one technology or another. Then, the model is post-processed before being thermoformed. Some printers of note capable of printing aligners and retainers are: Formlabs with Form 3B+ or the J700 Dental 3D printer from Stratasys.

Photo credit: Formlabs

Implants

Whenever we lose a tooth, this requires quick help through an implant, because otherwise the area around the missing tooth degrades due to insufficient stress. With the help of additive manufacturing, implants in the dental field can not only be produced on-demand and therefore faster, but also individualized. This is particularly important in dental healthcare, as each person’s mouth and smile is individual to them. With the precise manufacturing method of 3D printing for dental implant surgery, patients are not limited in any way in terms of their bite ability or chewing function, for example. In addition, 3D printing is also considered to be a more economical method that is constantly being improved through innovation and makes the production of dental implants much easier.

Photo credit: Formlabs

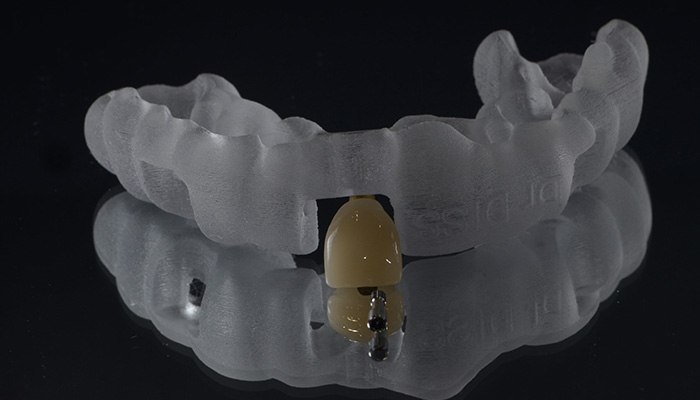

Surgical Guides

One use of 3D printing particularly valuable for dentistry of these is the surgical guide for dental implants. This is one of the latest advances and has revolutionized surgical processes even beyond dentistry. For as long as dental implants have existed, it has been very difficult for dentists to place them in the right places. Due to the inconvenient angles and the inability to see clearly, placement has been difficult for many dental professionals. As a result, many implants have been misplaced, which can lead to oral health complications. This is where surgical guides have come in to address these issues. Specifically, the guide helps dentists place dental implants correctly and in the right place. It is a single-use device designed to be placed directly on a patient’s teeth, and features a hole that allows an implant to be positioned in the right place, at the right angle and depth. This method offers more precision, about three times more than hand placement.

Photo credit: Arenas Dentistes

Anatomical Replicas and Models

Anatomical models are 3D representations of a part of the body, based on scans: for dentistry, these are of the jaw or the mouth. Models are used for planning and discussing surgical procedures, both between patient-clinician and clinician-clinician. They provide a detailed image of the area of interest and can reduce the risk of operating errors as the dentist has a tangible anatomical structure to work from. But where does 3D printing come into dentistry? While traditionally a plaster model can be made onto which crowns and dentures can be placed, this is a slow, manual process and involves a wait time for the model to be ready. 3D printing can be used to produce the models, based on intra-oral scans, in a fast and efficient manner as it is built layer by layer by the printer. Depending on the use of the model, different types of additive manufacturing are used. For basic models, FDM can be used with filament, but for more complex replicas SLA is used to produce resin models. While the use of traditional plaster-based methods is still common, 3D printing is becoming relatively popular for this purpose.

Photo credit: freepik.com

Dentures

The use of 3D printing to produce dentures is an emerging technology which has potential to streamline the process. While the traditional method of milling from a resin base is labor-intensive and involves several trips to the dentist, 3D printing could produce dentures in a quicker and less expensive way. While the method is not currently perfect, limited by aesthetics and low-resolution printers, there have been a number of positive indications: recently, new materials for denture production have been given the CE mark (that is, marked safe for purpose in the EEA) and patient studies have suggested that dentures are acceptable to the user. Some companies such as Formlabs already offer custom denture solutions; their website suggests cost savings of over half compared to completely milled teeth. The socio-economic impacts of additive manufacturing solutions are particularly intriguing, as we could see in the future the application of 3D printing to make dentures more available to those who need them the most.

This image shows a 3D printed denture set (left) and a milled set (right). Photo credit: Aegis Dental Network

Casting Patterns

3D printing can also be used for indirect dental processes. Although 3D printing is clearly being used to make end-use parts for dentistry including crowns and bridges, copings and substructures and more, it also has a role to play in making the castings. Dental casting patterns are accurate, three-dimensional replicas of a patient’s teeth and can be used not just to study the mouth but also to create crowns, fixed bridges and dentures. Anyone who has had orthodontic work or been to the dentist has had the experience of biting down into the uncomfortable wax to create this perfect mold. However, with 3D scanning and printing, the process is streamlined, with a highly accurate mold created by printing, washing and then removing unwanted supports, burnout, etc giving a final product.