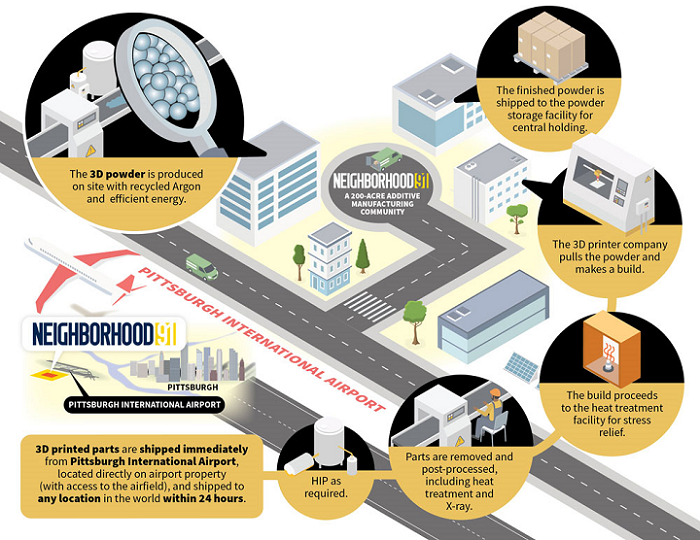

After much anticipation, Wabtec Corporation (NYSE: WAB) officially began operations at its new 3D printing facility in milieu 91, located at the Pittsburgh International Airport Innovation Campus. The new 11,000-square-foot facility is dedicated to additive production and will be used to develop the railway company's 3D printing capabilities.

The site already includes Large-scale SLM800 printer, which will be used to 3D print light and large-scale parts for Wabtec customers in the rail industry. These include aluminum items, such as brake parts, heat sinks for freight trains, and other components. The company believes that the use of 3D printing can cut waiting times by up to 80 percent in some cases.

As discussed in the interview we with Jennifer Coyne , a former wabtec global additives manufacturing (AM) leader, the company aims to print 3D 25,000 parts by 2025 to support its internal supply chain. The company's goal is to simplify its supply chain, as well as combine design improvements, at competitive prices.

"Advances in additive technology are changing the way we design and build the next generation of products that are business-critical and sustainable for our customers," said Eric Gebhardt, Wabtec's chief technology officer. "Neighborhood 91 and its unique additive ecosystem will help drive creative solutions to engineering challenges and breakthroughs in 3D printing. Our Neighborhood 91 facility and other additive laboratories in Western Pennsylvania will accelerate new innovations that shorten wait times, reduce costs, and improve reliability."

The new facility is part of Wabtec's initiative to use additive manufacturing to provide parts faster with a simplified supply chain, implementing advanced features that enhance applications, all at competitive prices. The company plans to use additive technology to produce more than 25,000 parts by 2025 to support the internal supply chain.

I am happy with Wabtec and Neighborhood 91. As mentioned in the 3DPrint our latest latest. with PRO article, US infrastructure failed. And, while not always sustainable, rail transport has the potential to be a more environmentally friendly way to travel and, depending on a number of factors , transporting goods over long distances. However, especially in terms of high-speed rail, the U.S. severely lacks a rail department.

With about two-thirds of its business dedicated to freight and a third dedicated to passenger rail, Wabtec helped modernize the U.S. rail industry. In addition to its aggressive additive program, the company is developing 100 percent battery-electric locomotives. In May 2021, he announce the results Testing technology testingFLXdrive - new , where flxdrive-powered trains run services across 13,320 miles in the mountainous San Joaquin Valley region of California for three months.

Wabtec determined that this battery-powered locomotive has 11 percent less fuel consumption and greenhouse gas emissions. Next, the company will build batteries with a capacity of more than six megawatts of hours, which it predicts will slash emissions and fuel consumption by up to 30 percent. The company aims to deploy a fleet of trains with this second generation flxdrive technology over the next few years. In the long run, Wabtec hopes to develop zero-emission locomotives using batteries, hydrogen internal combustion engines and hydrogen fuel cells, reducing the rail industry's carbon footprint by up to 300 tons per year.

Neighborhood 91 is the beginning of what could be an integrated industrial area model in the future. By placing businesses at Pittsburgh airports, campuses can streamline product shipments, which can impact emissions associated with transporting goods to and from the airport.

In addition, the site will feature argon gas recycling, through its first tenant, Arencibia- I'm not The company focuses on monitoring, analyzing and restoring noble gases, such as argon for 3D printing. By recycling argon gas used in AM metals, as SLM 800 does, Arencibia believes it can help reduce 60 percent of the cost of 3D printing associated with the use of argon or other noble gases. Because Rusal America will also be Neighborhood residents 91 , Wabtec may use aluminium ALLOW low carbon Russian companies , which is melted in factories mostly run by hydropower.

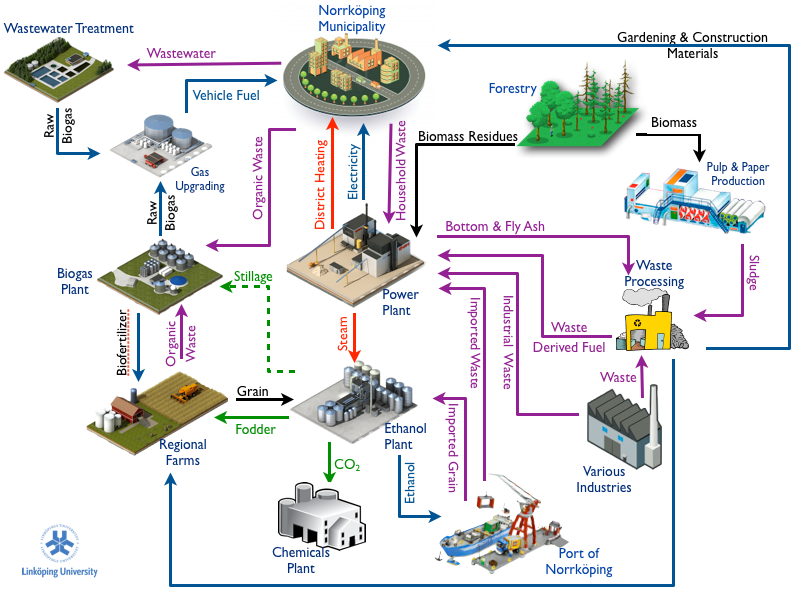

Our industrial society is still too far from ecologically sustainable operations, but Neighborhood 91 is a very small step in the right direction. It may not true - properly represents circular production and consumption, but basically does its best in the existing economic and manufacturing paradigms. Perhaps the next industrial estate inspired by Neighborhood 91 or future upgrades to its existing Pittsburgh campus will move closer tosolving industrial symbiosis .

For a strange inspiration for an integrated production facility, consider looking at that Solimene Ceramics Factory of Vietri sul Mare, Italy, built in 1954 by Paolo Soleri. As both a worker's residence and a ceramics factory, the building was designed in such a way that the production line rotates from top to bottom from start to finish.