Hardware and materials companies that will shape the industry in the years to come

3dpbm Research‘s recently released report on Composites Additive Manufacturing Opportunities 2020 – 2030 (hardware, materials and applications) presented a detailed picture of the current state of this segment with projections on the business potential for the next ten years. Out of the over 50 companies interviewed and analyzed for the report, we present a selection of the 15 composites additive manufacturing companies whose products stand to evolve into some of the most relevant short-, medium- and long-term opportunities for composites part production.

#1

Ingersoll

Opportunity: medium- and long-term

Ingersoll, a machine tool specialist and part of the Camozzi Group, produces 3D printing equipment and a range of Fiber Placement Machines for carbon fiber layup. In 2019, Ingersoll’s MasterPrint 3D printer—which prints with chopped fiber and continuous fiber materials—entered the Guinness Book of World Records as the largest plastic printer in the world. Ingersoll markets both hardware and materials for composite additive manufacturing.

#2

9T Labs

Opportunity: medium- and long-term

Zurich’s 9T Labs was founded in 2018 and provides a complete composites manufacturing solution comprising hardware, software and materials (including carbon fiber reinforced PA12 and PEKK), in addition to collaborative engineering assistance. Among composites additive manufacturing companies, 9T was the first company to bring to market a continuous composite 3D printer for serial part production, combining a manufacturing module with a post-processing module and offering process monitoring software. The all-in-one 9T Red Series solution is available as a subscription.

The Red Series 3D printer from 9T

The Red Series 3D printer from 9T

#3

Arris Composites

Opportunity: long-term

Arris Composites, founded in 2017 in Berkeley, California, has developed a proprietary technology called Additive Molding that combines 3D printing with traditional high-volume manufacturing. According to Arris, its Additive Molding technology allows for more precise alignment of fibers than is possible with other additive methods, letting engineers reinforce parts exactly where needed. Former Autodesk CEO Carl Bass joined the Arris Composites board of directors in April 2020 as part of the startup’s global expansion.

Arris composites’ Founder Ethan Escowitz.

Arris composites’ Founder Ethan Escowitz.

#4

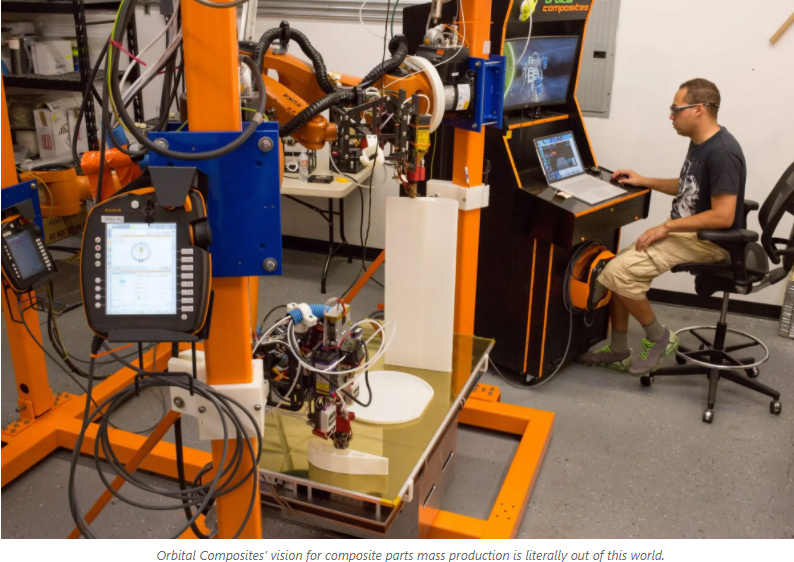

Orbital Composites

Opportunity: long-term

Based in San Jose, California, Orbital Composites produces a 3D printer called the Orb 1, designed for large end-use parts. Among composites additive manufacturing companies, Orbital also specializes in end-effectors, which are capable of processing a range of thermoplastics (including PEEK) and fiber tows (between 3k and 100k) for continuous fiber printing. Orbital also offers design and manufacturing services.

Orbital Composites’ vision for composite parts mass production is literally out of this world.

Orbital Composites’ vision for composite parts mass production is literally out of this world.

#5

Hexcel

Opportunity: medium- and long-term

Connecticut’s Hexcel Corporation is a global leader in composites technology specializing in carbon fiber reinforcements and aerospace materials. In 2017, Hexcel acquired the Aerospace & Defense (A&D) business of Oxford Performance Materials (OPM), which specialized in PEKK additive manufacturing materials and supplied 3D printed parts for the Boeing Starliner aircraft. The PEKK 3D printing composite is now marketed under the HexAM brand.

Hexcel’s HexAM part production brand now integrates composite PEKK powders as well.

Hexcel’s HexAM part production brand now integrates composite PEKK powders as well.

#6

ALM

Opportunity: short and medium-term

Advanced Laser Materials, part of the EOS Group, is a materials manufacturer offering high-performance composites for SLS additive manufacturing. The company is based in Temple, Texas. The ALM portfolio includes carbon and glass-filled nylon powders and other laser sintering materials. In addition to manufacturing composite materials, ALM also provides hardware services, laboratory services and custom material development.

ALM’s HT-23 is a PEKK composite powder specifically for EOS P810 systems.

ALM’s HT-23 is a PEKK composite powder specifically for EOS P810 systems.

#7

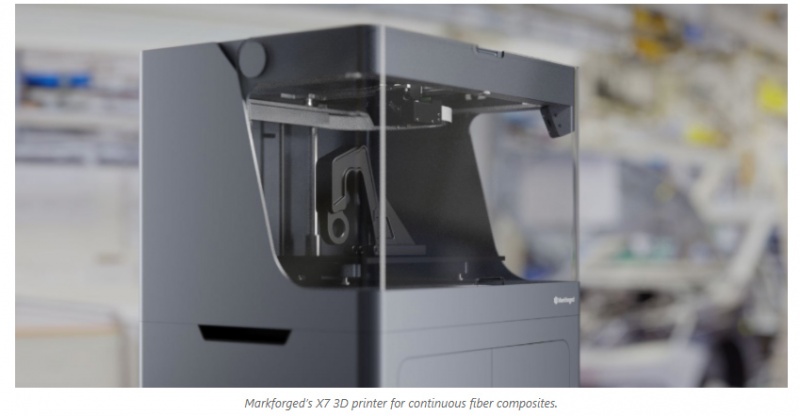

Markforged

Opportunity: short- and medium-term

Markforged of Massachusetts was the first company to offer continuous fiber 3D printing technology and remains the market leader in that segment. Founded in 2013, the company produces desktop and industrial-level 3D printers, which are built for a range of composites. Its high-end models (such as the popular Mark 2 and X7) can process any continuous fiber, while its more entry-level systems can process chopped carbon. Markforged also has its own portfolio of materials.

Markforged’s X7 3D printer for continuous fiber composites.

Markforged’s X7 3D printer for continuous fiber composites.

#8

Anisoprint

Opportunity: medium- and long-term

Founded in 2015, Moscow-headquartered Anisoprint is a composites specialist with its own range of 3D printers, materials and software. Anisoprint has developed its own form of continuous fiber 3D printing called Composite Fiber Coextrusion (CFC). CFC printers use two separate spools — one for the thermoplastic, the other for the reinforcing materials — fed into a single extruder. This technology allows the user to control fiber volume ratio and specify “complex curvilinear trajectories” to create internal lattice structures.

#9

Desktop Metal

Opportunity: medium- and long-term

Massachusetts-based Desktop Metal is a 3D printer manufacturer offering metal printing solutions in a range of machine sizes and formats. The company’s Fiber system, launched in 2019, processes continuous carbon fiber and fiberglass tape in a proprietary process called Micro Automated Fiber Placement (μAFP). The system prints with two printheads: one for the tape; another for chopped carbon fiber and fiberglass-reinforced filament.

Desktop Metal’s Fiber, the company’s first entry into the composites additive manufacturing market.

Desktop Metal’s Fiber, the company’s first entry into the composites additive manufacturing market.

#10

Arevo

Opportunity: short- medium- and long-term

Founded in 2013, Arevo is the hardware manufacturer behind Direct Energy Deposition (DED) technology, which can process composites containing more than 50% carbon fiber. With its industry-grade Aqua platform, Arevo was the first company to offer a MaaS (Manufacturing-as-a-Service) business model for composite parts, pairing product designers with global partners for “hyper-local” production. Areva is headquartered in Santa Clara, California, but in June 2020 announced the opening of a large MaaS facility in an as-yet-undisclosed Asian city. Among the composites additive manufacturing companies, Arevo is one of the first to market a composites 3D printed consumer product, the Superstrata bike.

Arevo’s Superstrata composites 3D printed bike.

Arevo’s Superstrata composites 3D printed bike.

#11

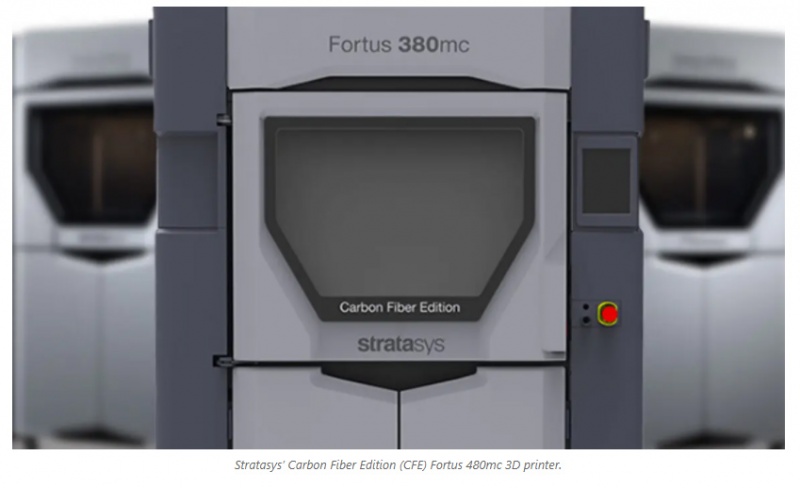

Stratasys

Opportunity: short- and medium-term

AM global leader Stratasys markets an affordable carbon fiber FDM 3D printer called the Fortus 380mc Carbon Fiber Edition (CFE), in addition to several composite materials for its high-end machines. The 380mc CFE prints in two materials: FDM Nylon 12CF Carbon Fiber, and ASA. Both are compatible with soluble support. Stratasys says its Nylon 12CF has the highest strength-to-weight ratio and stiffness of any FDM material.

Stratasys’ Carbon Fiber Edition (CFE) Fortus 480mc 3D printer.

Stratasys’ Carbon Fiber Edition (CFE) Fortus 480mc 3D printer.

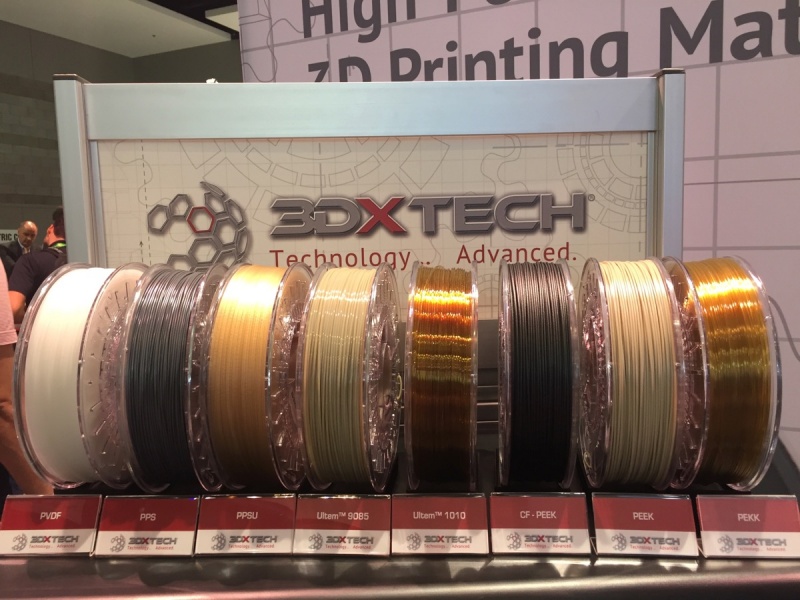

#12

3DXTECH

Opportunity: short- and medium-term

Headquartered in Grand Rapids, Michigan, materials manufacturer 3DXTech offers the market’s largest selection of chopped fiber composite filaments for thermoplastic extrusion. 3DXTech has been active since 2014, and its portfolio includes high-performance filaments like a carbon fiber reinforced PEKK-A (CarbonX brand) and a glass fiber reinforced PEEK (ThermaX brand). In 2019, the company launched its own composites-friendly, high-temperature 3D printer, the GEARBOX HT2, which is not restricted to 3DXTech materials.

A selection of 3DXTech advanced materials.

A selection of 3DXTech advanced materials.

#13

BASF/Toray

Opportunity: medium- and long-term

BASF, the world’s largest producer of chemicals, signed a supply agreement with fiber producer Toray Advanced Composites in August 2019. Toray now uses its glass and carbon fibers to reinforce BASF polyamide resins. In August 2020, BASF acquired XSTRAND, a line of glass fiber reinforced FDM filaments, from fiberglass specialist Owens Corning, and the chemicals giant also has a composites-focused partnership with Impossible Objects.

BASF Forward AM acquired the XSTRAND from Owens Corning.

BASF Forward AM acquired the XSTRAND from Owens Corning.

#14

Vartega

Opportunity: medium and long-term

Colorado-based Vartega specializes in the recycling of advanced materials like carbon fiber. Using its patented recycling process, the company has developed a low-cost grade of carbon fiber that behaves similarly to virgin material. Founded in 2014, Vartega sells its materials in various forms, including VartegaFil, a recycled carbon fiber FDM 3D printing filament available in an ABS or PLA version.

Vartega’s recycled carbon fiber filament materials.

Vartega’s recycled carbon fiber filament materials.

#15

Victrex

Opportunity: long-term

British company Victrex is a high-performance polymer supplier offering composite additive manufacturing solutions. The company’s new PAEK 3D printing materials are optimized for either FDM or laser sintering and are currently in the beta testing phase. In 2019, Victrex invested in Bond High Performance 3D Technology, a Dutch company that is supplying 3D printing hardware and software for the development of Victrex’s PAEK materials.

Victrex could become a relevant player in CRP with advanced materials.