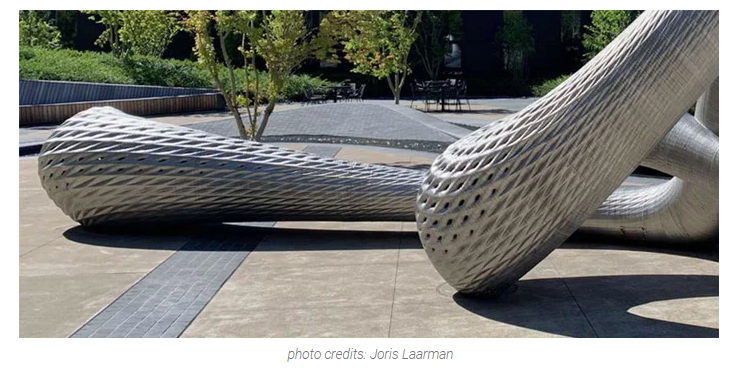

MX3D, a specialist in the WAAM (Wire Arc Additive Manufacturing) process, has unveiled its latest construction project: a 3D printed metal bench, with a rather surprising design, as it is shaped like an open loop. Named Oregon Dragon Bench, this structure was installed in front of the LeBron James Building in Beaverton, Oregon. The building is used as the innovation center of the Nike World Headquarters. The 3D printed bench measures 10m x 3m x 2.5m (~33’x 10′ x 8′) and was manufactured using MX3D’s innovative robotic 3D printer.

If the name MX3D sounds familiar, it’s probably because you’ve already heard of the company’s 3D printed metal bridge , which was successfully installed in the heart of Amsterdam. Measuring 12.2 (~42′) meters length, 6.3 (~21′) meters width and 2.1 (~7′) meters height, the massive object required 6 tons of steel in total to be made! It was a weary and time consuming process for the teams, who combined their expertises in design and additive manufacturing to create the imposing structure. In this, most recent production, the man behind the concept is no other than Dutch designer and entrepreneur Joris Laarman, who is renowned for his work inspired by emerging technologies.

Photo Credits: Joris Laarman

Besides the fact that this bench is eye-catching and quite different from the structures we are used to seeing in parks, the bench is a real work of art thanks to its design. Joris Laarman integrated a structural gradient, that provides all the structural stability while optimizing the total weight of the bench. In more concrete terms, he used topological optimization to identify the points that were exposed to the most weight and then placed the material only where it was absolutely necessary.

Using MX3D’s 3D printing technology, the designer was able to create these complex, interlocking shapes – making the bench look like it is forming a kind of loop. He also mentioned that he has reduced both manufacturing time and costs compared to traditional methods and powder-based additive manufacturing processes. While the exact weight and the production time yet still remain a mystery, it is safe to say that creating such an amazing object is an outstanding accomplishment! Feel free to visit the artist’s website and take a look at his other projects and to better understand how 3D printing and design can be combined.

*Cover Photo Credits: Joris Laarman