Metal machine manufacturer AML3D is beginning production of a pressure vessel for U.S. oil company ExxonMobil. It is a $190,000 contract to design an 8-meter by 1.5-meter diameter part, making it the largest commercial 3D printed commercial pressure vessel on the market. The manufacturer states that it will be able to produce the component which weighs over 2000lbs in just 12 weeks using its WAM technology.

The pressure vessel is another exciting project in the Oil & Gas sector, which has increasingly been banking on additive manufacturing to design parts faster and cheaper. In fact, a study conducted by the consulting firm GlobalData stated that additive manufacturing in the oil and gas industry is expected to reach $32 billion by 2025 worldwide, and more than $60 billion by 2030. Proof that 3D technologies have a role to play in such a demanding sector.

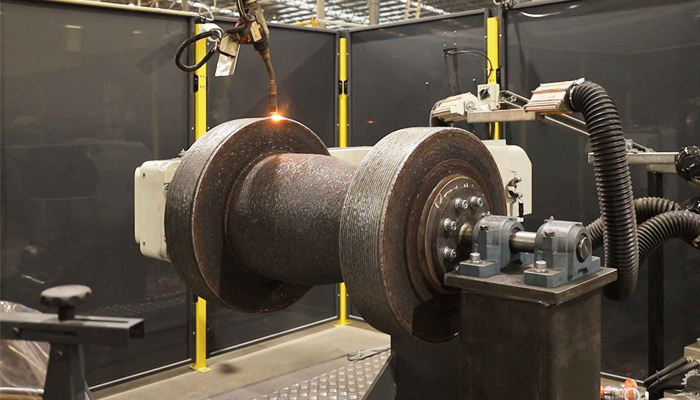

Last November, AML3D 3D printed the largest pipe spool on the market (photo credits: AML3D)

WAM Technology Makes a 3D Printed Pressure Vessel

AML3D has developed a 3D printing method based on the Directed Energy Deposition (DED), called WAM for Wire Additive Manufacturing. The machine deposits metal wires layer by layer, with the ability to print a variety of different materials including aluminum, titanium, steel or nickel alloys. Since the solution does not have a closed printing chamber, the user benefits from an open manufacturing space with localized inert gas and the technology can also repair damaged parts directly. It is a process that reduces manufacturing costs and time while optimizing material properties. This is undoubtedly what led ExxonMobil to choose this technology to produce its pressure vessel. Indeed the technology already proved its worth when last year AML3D made the largest, verified oil & gas piping component.

The part in question will weigh about 2072lbs with a length of 8 meters and a diameter of 1.5 meters. It will be used in the US refinery operations and is expected to undergo strength and hydrostatic pressure testing for certification. AML3D director Andrew Sales added: “Signing this deal with ExxonMobil is a further demonstration of delivery against our multi-phase growth strategy. We have a major focus on building our capability and presence in the global Oil and Gas sector as an immediate value driver for the business and this contract absolutely aligns with that objective.” The tank will be manufactured by five of the eight ARCEMY printers installed in Adelaide, Australia. They will run at 75% capacity. The capacity utilization of the printing facility during this period will be 75%.

Andrew Sales, Managing Director of AML3D (photo credits: Adelaide Now)

AML3D claims that, with its technology, it will be able to deliver the component in record time: where it would typically take 12 months to get the tank, only 12 weeks would be required with metal additive manufacturing. Andrew Sales continues, “Our proven WAM® technology disrupts traditional industrial-scale metal manufacturing by producing superior components with a significantly shorter production cycle and a far more sustainable methodology involving less waste and lower energy input. Our understanding is, due to supply chain constraints, some traditional manufacturers were estimating a delivery date in excess of 12 months. AML3D will deliver a superior component in less than half that time.” You can find more information HERE.

*Cover Photo Credits: AML3D