Additive manufacturing service provider 3D Metalforge has launched a new 3D printing facility in Singapore with a farm of Ultimaker machines.

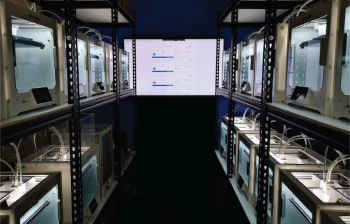

The new space, believed to be the largest of its kind in Southeast Asia, aims to ramp up the company’s 3D printing capacity for customers in the defence, maritime, medical, and oil and gas industries using a suite of 21 Ultimaker S3 polymer extrusion desktop 3D printers.

“We deal with clients from blue-chip companies that have stringent criteria on the production of end-use parts. It is thus imperative that we invest in reliable FFF 3D printers that can meet our needs and benchmarking standards”, said Mr Matthew Waterhouse, CEO of 3D Metalforge. “Ultimaker also has an open solution that allows us to work with over 150 materials. This has enabled us to experiment and/or print with the most suitable material, depending on customers’ needs. Furthermore, I am pleased with the excellent after-sales support that I have received to date.”

In a press release, the company added that material choice was a big consideration in its decision to partner with Ultimaker, swayed by the 3D printer manufacturer’s Material Alliance which consists of more than 80 contributing companies including major material brands like BASF, DSM and DuPont. 3D MetalForge also stated plans to realise a “local, distributed additive manufacturing vision” using Ultimaker’s Digital Factory software platform which would potentially allow the company to shift production between this facility and its upcoming factory in Houston, Texas, based on demand.

Mr Benjamin Tan, Vice President of Ultimaker APAC added: “With FFF 3D printing, lead time is often halved, as compared to conventional methods like injection moulding. This allows companies to have quicker go-to-market strategies. A printed prototype also allows close examinations for modifications, and customisations before embarking on mass-printing. This helps companies save costs before committing to bulk print orders. We are confident that Ultimaker is well-poised to support 3D Metalforge’s journey in FFF 3D printing.”

3D Metalforge is currently lending its facility to print various parts for COVID-19-related projects but also has its eyes set on expansion as it looks to recruit eight trainees from The SGUnited Traineeships Programme and an additional four engineers.