3D bioprinted organs, especially hearts, are slowly becoming a reality. Learn about the most promising 3D printed heart projects of 2020.

3D PRINTED HEART

Bioprinting 101

3D bioprinting is the use of additive manufacturing techniques that combine cells, compounds, and biomaterials to create bioengineered tissues and structures. Unlike traditional FDM 3D printing, bioprinting uses something called bioink, a mixture of organic and inorganic materials, to make models.

As you can imagine, this technology is very important for the medical industry. Its primary use would be to save the lives of millions of patients who are in need of a replacement organ or transplant. As it stands, around 20 people die every day in the United States waiting for a replacement organ.

To make things worse, host rejection of the organ can require another replacement down the line. Being able to 3D print artificial organs using patients’ own cells can help eliminate both transplant rejection issues and organ deficit in the transplant sector.

To date, a complete 3D bioprinted heart has not yet been successfully made or transplanted. However, many companies and research groups have been inching their way towards a fully-functional 3D printed heart. Let’s jump into some of the most promising projects.

3D PRINTED HEART

WFIRM: Bioengineered Cardiac Tissues

WFIRM develops more than 30 different tissues and organs (Source: Wake Forest School of Medicine)

Dr. Anthony Atala, the director of the WFIRM, is a huge name in the field of 3D bioprinting. Several years ago, his team engineered (not 3D printed) and transplanted bladders into living patients. At present, the institute develops more than 30 different tissues and organs.

HOW THE INNOVATION WORKS

In April 2018, the WFIRM team published a paper describing how they 3D bioprinted functional and contractile cardiac tissue using rat heart cells. These cells were suspended in bioink and printed into structures similar to human heart tissue.

They were able to test the effects of hormones like adrenaline and carbachol, which resulted in the expected change of heart rate in the printed cardiac tissue, just like what happens in organic structures.

LATEST DEVELOPMENTS

In early 2020, WFIRM announced the creation of a miniaturized human body “model”, containing different bioengineered human tissues that will be used specifically for drug testing. The tiny organoid structures are approximately one-millionth the size of an adult’s and include mini heart tissues.

Dr. Atala says that the most important capability of the mini-human lab model is “to determine whether or not a drug is toxic to humans very early in development”, making a huge impact on experimental drug testing.

To take a tour of WFIRM’s lab and hear more about what they’re working on, check out the video below.

3D PRINTED HEART

Tell Aviv University: Miniature Heart

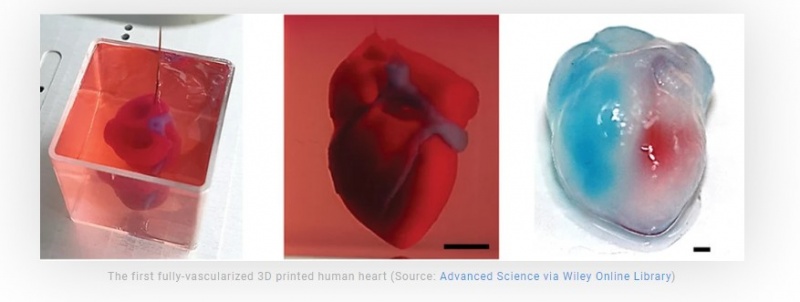

In April 2019, global news was flooded with the announcement of a successful 3D printed heart coming out of Tel Aviv University’s School of Molecular Cell Biology and Biotechnology.

It was the first time a fully-vascularized human heart was entirely 3D printed using human cells. And while it was a miniaturized model, it’s a huge accomplishment and a major step towards functional human organ bioprinting.

HOW THE INNOVATION WORKS

The human cells were taken from the test subject’s fatty tissue and reformed to become stem cells, which then enabled them to differentiate the cells into the various types of cardiac cells present in the heart. These new “cardiac” cells were mixed with inorganic materials to make bioinks that were finally 3D printed.

By using the patient’s own cells, the idea is to eliminate any chance of rejection of the newly bioengineered organ. Rejection is a major issue with organ transplantation, and unfortunately, many heart recipients show symptoms within the first year after surgery.

The next challenge for TAU’s team is to mature these differentiated cells and make them function as intended. Professor Tal Dvir, who led the research team, hopes that, within 10 years, “there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely.”

Watch this video from the Washington Post, which reports on the lab’s work. You’ll see up close how they’ve created the mini heart.

3D PRINTED HEART

Harvard Lewis Lab: Novel Bioprinting Technique

Yet another big player in the bioprinting field, the Lewis Lab at Harvard’s Wyss Institute for Biologically Inspired Engineering has recently announced a new technique that can potentially help 3D printed hearts become a reality. The laboratory is led by Professor Jennifer A. Lewis, for whom the lab is named after.

HOW THE INNOVATION WORKS

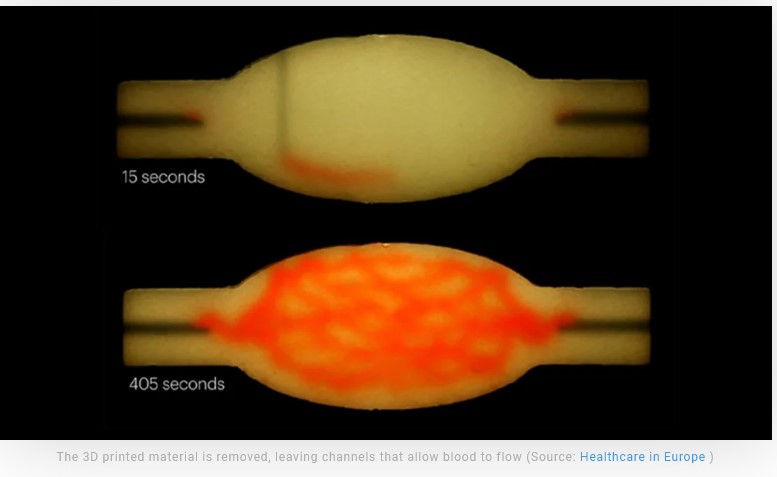

This new bioprinting technique is called SWIFT, an acronym for sacrificial writing into functional tissue. This technique takes living cells as matrices and 3D prints vascular channels into them. The 3D printed material is then removed by applying heat, leaving channels that should function as vascular structures which allow blood to flow through.

Regular 3D bioprinting techniques work with cells that require maturation in a bioreactor in order to “come alive” and acquire the specific function needed within the 3D printed organ. The bioinks used in these techniques also lack the actual density of human tissues. The SWIFT technique bypasses both issues since it works with living cells already packed in the desired density.

The research team successfully 3D printed vascular channels into living heart-derived cells, creating a cardiac tissue that beats just like a living heart. This tissue was kept alive and beat synchronously for seven days, proving that the 3D printed vascular channels function as intended.

Here’s a video that shows more about SWIFT and the processes ongoing in the Lewis Lab: https://vimeo.com/356467677

3D PRINTED HEART

Biolife4D: Miniature Heart

The Chicago-based company Biolife4D’s goal is to successfully bioengineer and 3D print human hearts for transplant purposes.

In 2018, they successfully demonstrated the actual bioprinting of a patch of human heart tissue, meaning the tissue had blood flow and could contract like a real heart. These cardiac tissue patches can be used to restore parts of a damaged heart in patients with acute heart failure.

HOW THE INNOVATION WORKS

To produce these patches, a 3D digital model of the patient’s heart is taken through an MRI machine. Then, a bioink is created using the patient’s own heart cells, combined with nutrients and other biomaterials. Finally, the tissue patches are 3D printed and matured in a bioreactor to make them transplant-ready.

LATEST DEVELOPMENTS

In September 2019, the company announced yet another major breakthrough: its first successful 3D printed mini-heart. According to the company, it replicates many of the features of a human heart and was created using its own bioink with human heart properties. Biolife4D has also refined its bioprinting algorithm, optimizing it specifically for heart 3D printing.

According to Biolife4D, with this new milestone, it’s only a matter of “optimizing our process and scaling up the technology” to achieve their ultimate goal: a full-sized and functional 3D printed heart that’s successfully transplanted.

Watch Biolife4D’s informational video about printing hearts below https://vimeo.com/316848296

3D PRINTED HEART

ETH & SAT: Artificial Heart Valves

Although not bioprinted, in 2017, a team of researchers from ETH Zurich, a science and technology university in Switzerland, published a paper describing the development of a functional beating heart 3D printed in silicone.

Roughly the same size as a human heart and imitating the same function (see video below), their work demonstrates how we’re quickly approaching the ability to replace hearts without the need for transplants.

HOW THE INNOVATION WORKS

Just like a real human heart, this silicone version has left and right ventricles as well as a chamber that drives the pumping action via pressurized air. The main limitation of the project is that the 3D printed heart only lasts for roughly 30 minutes or 3,000 beats before the material degrades and weakens.

LATEST DEVELOPMENTS

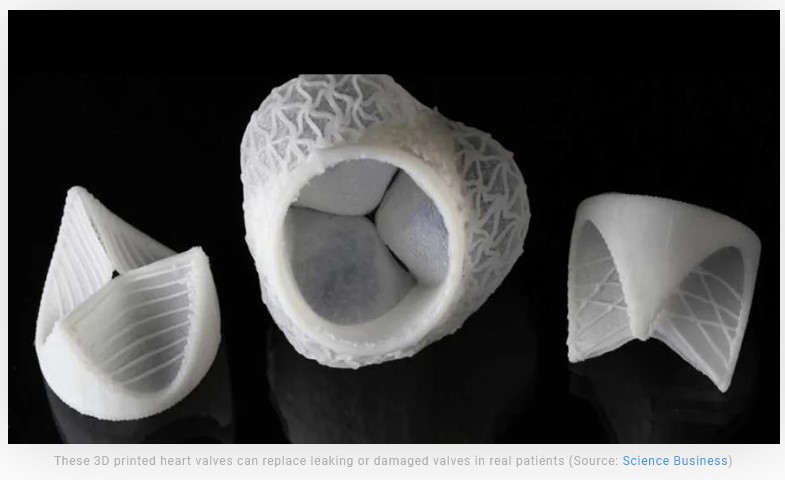

In 2019, the same research group, in collaboration with the South African company Strait Access Technologies, developed artificial 3D printed heart valves that can replace leaking or damaged valves in real patients. These parts were 3D printed in body-compatible material and provide the same blood flow functionality as conventional replacement valves.

Although artificial heart valves for transplant already exist, the ones developed by the Swiss researchers will be custom-made for each patient. Thanks to MRI and CT imaging, each valve can be specifically designed for a perfect fit.

This video shows how the silicone heart works: