While definitely interested in other AM materials such as polymer, wood, and resin, Massachusetts-based Desktop Metal (NYSE: DM) is, first and foremost, a metal 3D printing company; it is in the name, after all. The 3D printing unicorn-turned-publicly-traded company announced that it had been working with Uniformity Labs to sinter aluminum using binder jet technology, and that it had qualified 316L stainless steel for high-volume additive manufacturing with its industrial Production System, which uses patent-pending Single Pass Jetting (SPJ) technology. Now, it’s been revealed that the company has qualified 4140 low-alloy steel for high-volume printing of end-use parts, again for the DM Production System.

This material is considered to be an extremely versatile one in the low-alloy steel family, as it’s heat-treatable and therefore can be used in the automotive, industrial, and oil and gas sectors for applications like bolts and nuts, downhole tool components, couplings, gears, and spindles. Desktop Metal claims to be the first, and only, company so far to qualify 4140 low-alloy steel for use with metal binder jet printers.

“4140 has been a challenging material for metal binder jetting because of its low alloyed content, tight carbon control requirements, and low ignition energy, which together require advanced binder chemistry, as well as extensive printing and sintering optimization and atmospheric controls for safe processing. We are excited to be the first to qualify 4140 for metal binder jetting to enable this versatile material for the AM industry,” stated Jonah Myerberg, Co-Founder and CTO of Desktop Metal. “With the speed of the Production System, businesses can now use binder jetting to print complex 4140 parts at competitive costs while maintaining the strength and mechanical properties of traditionally manufactured alternatives. This is a game-changing solution for manufacturers who have been tied to time-consuming and expensive machining and conventional tool-based manufacturing processes.”

This all-purpose steel material, which features high tensile strength, toughness, and resistance to abrasion and impact, has been validated by the company’s materials science team, which concluded that 4140, printed on the DM Production System and sintered by Desktop Metal, meets Metal Powder Industries Foundation (MPIF) 35 standards for structural powder metallurgy parts. So now this low-alloy steel can be used to mass produce strong, 3D printed parts that should hold up well under mechanical stress and high temperature and impact.

According to Desktop Metal, parts 3D printed out of 4140 on its Production System show a major decrease in part cost and production time in comparison to other conventional manufacturing methods, and can also reduce material waste and eliminate tooling. The Production System has two printer models—the P-1 for serial production and the large-form P-50 for mass production—and pairs an open materials platform with Desktop Metal’s own engineered binders. The printer’s inert processing environment makes the system compatible with many materials, like titanium, aluminum, and now 4140 low-alloy steel for end-use parts.

Examples of some of these parts include a power steering joint, which is used to transfer power between a car’s electric power steering motor and steering shaft. In particular, the spline teeth of this part that connect it to the rest of the assembly benefit from 4140’s great strength and hardness. Instead of using a conventional, costly mold during pressing and sintering, 3D printing this part on the Production System P-50 means less lead time, no tooling, and flexible design.

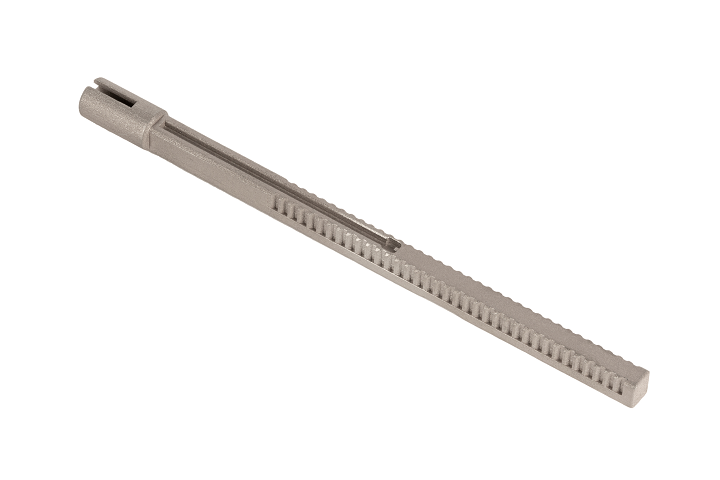

4140 can also be used to 3D print lever drives, which help adjust the location of machine components in a linear fashion; binder jet technology is particularly helpful here in terms of the precise grooves needed to locate the position of any external components. Due to machining labor and tooling costs, it wouldn’t be very cost-effective to print a mid-volume run of 10,000 of these parts using conventional manufacturing, but Desktop Metal says its Production System P-50 can handle the job in less than one week.

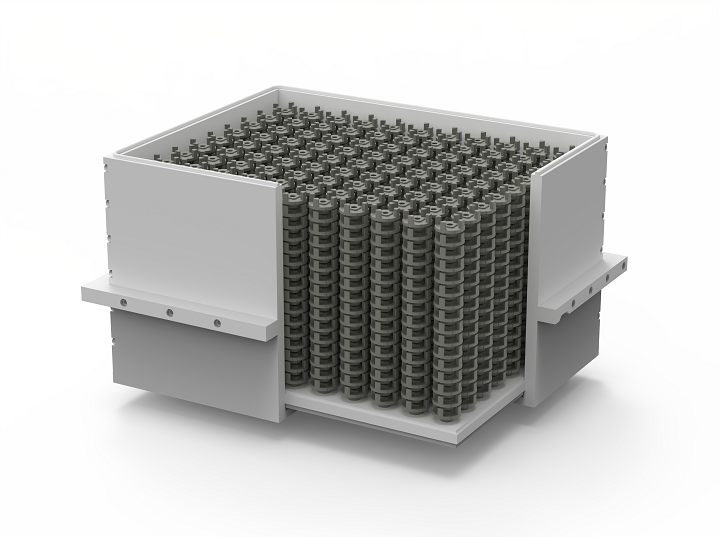

The hardness of 4140 low-alloy steel is particularly good for herringbone gears, which are used in many industrial machinery applications and can be lightweighted through the complex lattice designs that 3D printing can create, which decreases material costs as well as wear on external components, like bearings and motors. When nesting 120 of these gears in a build on the Production System P-50, Desktop Metal says it’s possible to mass produce them in quantities of up to 200,000 a year.

This newly qualified material can also be used to print linear pneumatic pistons, which use a rack and pinion to convert air pressure into rotary motion. Using 4140 for this application is said offer improved toughness and wear resistance to these parts, which are typically assembled out of many components due to the lack of complex geometry that conventional manufacturing can offer.

According to the new “Metal Parts Produced 2021: Additive Manufacturing Applications Market Analysis” report by SmarTech Analysis, the onset of the COVID-19 pandemic threw global manufacturing “into a state of prolonged turmoil,” from which it’s still trying to recover. While Desktop Metal reported net losses of $59.1 million in the first quarter of 2021, it also announced that revenue was up 35% from the previous quarter, and CFO James Haley said the company not only expects to generate revenue of more than $100 million for the full year, but also to see sequential quarterly growth throughout 2021. Qualifying more materials for its Production System should definitely help in this endeavor.