The James Dyson award is an international competition led by the eponymous entrepeuneur. It rewards engineering or design projects which ‘solve a problem’, and the Polyformer certainly does this. Reiten Cheng and Swaleh Owais have developed a machine which recycles plastic from water bottles into filament for FDM 3D printing, making it accessible for developing countries. The project was the recipient of the prestigious Sustainability division of the James Dyson Award.

The designers were inspired by a 3D printing website which features recycling and sustainability stories. They wanted those in developing countries to be able to benefit from 3D printing technologies while also repurposing waste materials. Owais completed this project in Rwanda at the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, hoping to make a product which can solve the high shipping costs of filament into Africa.

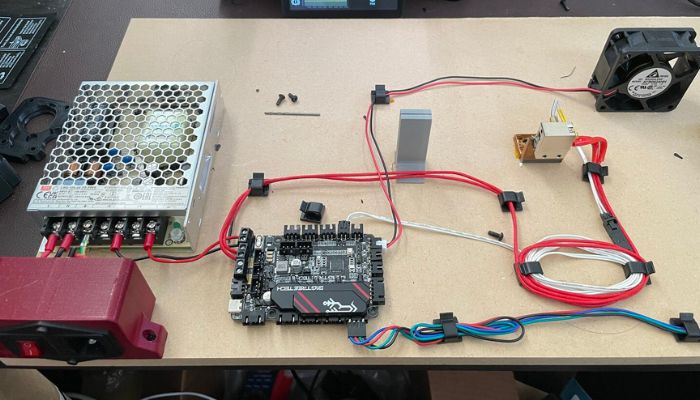

Construction of the Polyformer machine. (Photo credit: Reiten Cheng)

Recognition and Awards

The Polyformer was awarded the James Dyson award for Sustainability, chosen by the inventor himself. The Award is given every year to innovative projects and the pair will use the prize money to produce more Polyformers for use in 3D printing labs in Rwanda. This can go some way to solve litter by recycling plastic. They plan to then collect user feedback and expand the project to other developing countries. Further side projects to complement the Polyformer are also in the works; for example, the Polyjoiner will automatically connect filament strands together and the Polydryer will evaporate water from PET to prevent negative print quality. Finally, the Polyspooler will automatically create spools of filament for ease of use.

Sir James Dyson, Founder and Chief Engineer at Dyson commented, “By turning used plastic bottles into 3D printer filament, Polyformer helps reduce the amount of waste going to landfill and provides a cheap and plentiful material for engineers and designers, especially in developing countries. Their idea will provide new opportunities for other inventors to prototype their ideas using 3D printing.”

The Technical Stuff

The Polyformer has a modular architecture. To make the filament, a slicing tool can cut the plastic bottle into a ribbon to be fed into the hot end. The ribbon is thermoformed into a 1.75mm filament, which can be mounted to the motorized spool. Once this filament is made it can be transferred o a 3D printer. The Polyformer is designed to be built with mainly 3D printed parts to make it more accessible globally. Furthermore, all the technology is open-source. The designers made the decision to make it publicly available without a patent so that others may create their own. Other criteria chosen by Cheng and Owais were a simplified process, avoiding supports and post-processing as much as possible to create a compact, easy to assemble and easily modifiable machine.

The complete Polyformer machine. (Photo credits: Reiten Cheng)

The Polyformer innovation lies in its dual benefits of waste prevention and improved accessibility of 3D printing to developing nations. They are not the first to seek to reuse waste products – for example, a US company will build 10 homes using recycled plastic. On a smaller scale, researchers in Singapore have used recycled glass for sand printing. You can find out more from the designer’s website HERE, and more information about the James Dyson Award can be found HERE.