nTopology and Japan’s Yamaichi Special Steel (YSS) signed a Memorandum of Understanding (MoU) to discuss and define the partnership to promote nTopology’s new generation nTop software in Japan.

Yamaichi Special Steel is an integrated part of the Japanese automotive and heavy industry manufacturing supply chain. The Additive division of YSS was started in 2017 and has promoted the additive manufacturing and DfAM in the local automotive, medical and aerospace industries.

The partnership will include in the first part the reseller and service agreement, where Yamaichi Special Steel will bring the nTop solution to its customers based in Japan. Yamaichi Special Steel will provide the necessary training and support to the users in its fields of expertise. The idea of the first phase of the partnership is also to bring added value, helping nTop users to innovate products.

The second phase of the partnership will be interconnecting the Cognitive Additive solution of Yamaichi Special Steel to the nTop platform. The creation of such tool-kits will help users predict the printability and cost of a part while designing it.

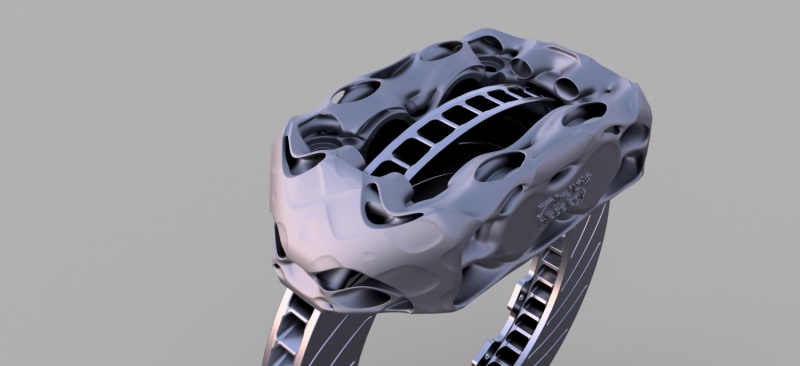

To initiate this partnership with nTopology, the YSS Additive Manufacturing team redesigned a brake caliper using topology optimization. The part was topology-optimized from a design space using realistic load cases. As the brake caliper works in a high temperature and fatigue environment, YSS designed a TPMS based heat exchanger structure. An oil circuit, optimized for pressure loss, was also added. Shielding surfaces underneath the caliper were added to prevent impact damages from environmental factors such as gravel impacts. The part was optimized for L-PBF (laser powder bed fusion) manufacturing, using AlSi10 (aluminum alloy) as material.