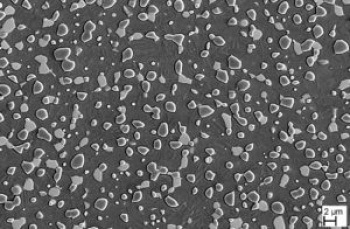

VBN Components, Uppsala, Sweden, is launching what it calls “the world’s hardest near-net-shape steel”. Vibenite® 290 is an alloy with a high hardness and high carbide content (in its fully-hardened condition, around 25 vol.%), which the company states makes it a realistic alternative to cemented carbides for many high wear and high temperature applications.

According to VBN, the alloy is especially suitable for applications where erosion and abrasion are a concern, such as metal cutting tools – typically made from forged and rolled metal bars that must be drilled, milled and turned to create tools and components. Because Vibenite 290 can be processed to near net shape by Additive Manufacturing, tool production could be made significantly more efficient.

“We interact daily with customers who have very specific requirements regarding materials performance concerning wear and heat resistance,” stated Martin Nilsson, VBN CEO. “To meet their needs, we have developed a material with excellent qualities, and which can be ordered in near-net-shape.”

Ulrik Beste, VBN CTO, added, “The limitations of traditionally-made products result in a compromise. Instead of choosing the material best-suited to the product in mind, producers are instead forced to use a material that they can process. By focusing on material performance, we turn this completely around.”

“We have shown in a customer test that this product lasts many times longer than before. And we know that even higher performance is possible,” he concluded.