Wiss researchers have developed a new, high-precision method for 3D printing small, soft objects. The process, which takes less than 30 seconds, has potential applications in a wide range of fields, including 3D bioprinting.

The groundbreaking 3D-printing method, was detailed in the journal Nature. Researchers at the Swiss Federal Institute of Technology (EPFL) based their discovery on the principle of tomography — the technique for displaying a representation of a cross-section through a solid object, using x-rays or ultrasound.

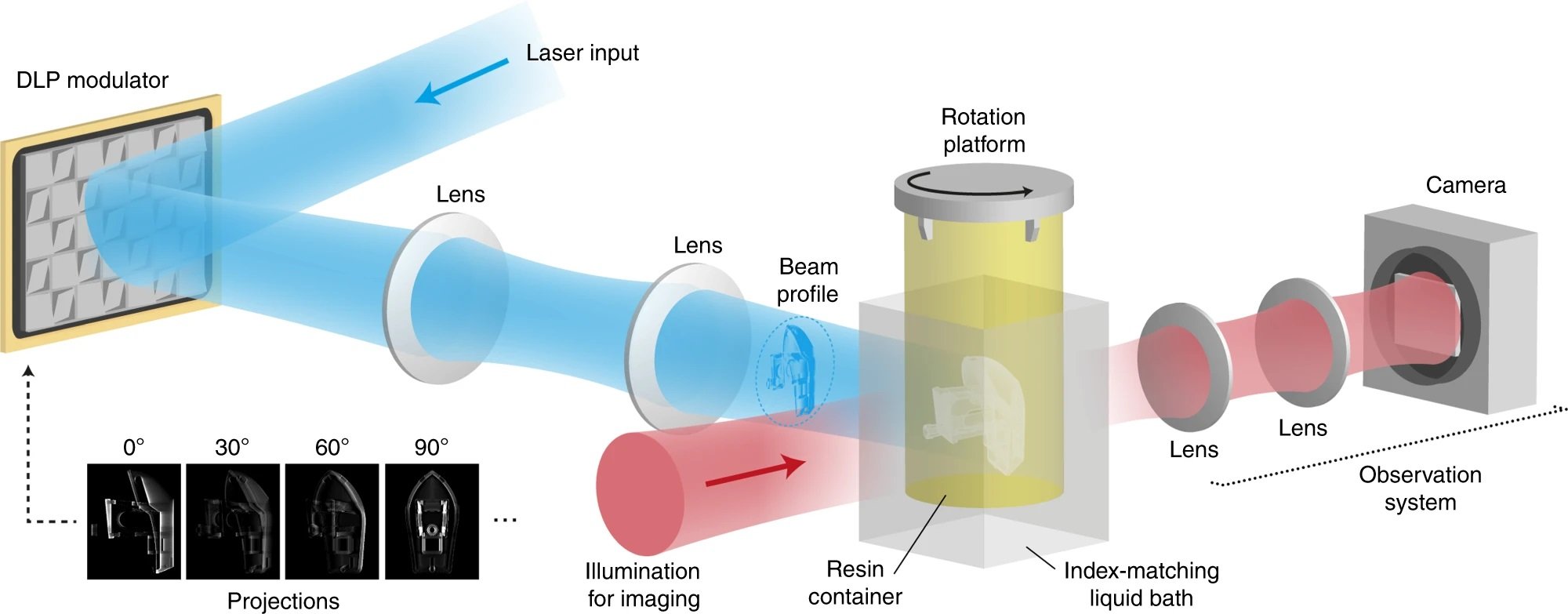

To print an object, a photosensitive resin is illuminated from multiple angles in a volumetric 3D printer with pre-computed dynamic light patterns.

The three-dimensional accumulation of light inside the build volume results in the solidification of the desired object in a matter of seconds.

Experimental setup for high-resolution tomographic printing (Source: Nature.com)

Experimental setup for high-resolution tomographic printing (Source: Nature.com)

“Conventional 3D printing techniques, known as additive manufacturing, build parts layer by layer,” explains Damien Loterie, the CEO of Readily3D, a company set up to develop and market the system. “The problem is that soft objects made that way quickly fall apart.”

The technology could have innovative applications in a wide range of fields, especially for medicine and biology. The method could be used to make soft objects such as tissue, organs, hearing aids, and mouth guards.

The system is currently capable of making two-centimeter structures with a precision of 80 microns. However, as the team develops new devices, they should be able to build much bigger objects, potentially up to 15 centimeters.