The next generation in regenerative medicine, human-machine interfaces, synthetic biology and futuristic medical devices

Foto: Image created by inputting the terms 4D bioprinting and cyborganics into the AI app Dream by Wombo.

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

When I first heard of 4D, I thought it was nothing more than a marketing gimmick. I was starting to feel like we were staring down the barrel of a gun and avoiding the rabbit holes of the current need for improved realistic applications with limited technological complexity. It seemed that we were just adding a new number in front of the term “dimensional” to appear unique and innovative. In my previous news article, I addressed the question “Is it the end of extrusion 3D bioprinting?” not to create controversy in the industry but to spark a dialogue. Extrusion 3D bioprinting is perfect for entry-level technology. We now need to start using advanced 4D tissue engineering technologies and cyborganic biomaterials to address the differences between the hype and reality of realistic regenerative medicine, human-machine interfacing, and futuristic medical device applications. Feedback from one industry expert was that we need this type of thought leadership; otherwise, there is the danger of buying into our hype and creating an echo chamber. As a writer, I am always chasing my own analysis, imagination, and opinions, so this quote reminded me of something more valuable—to avoid making the same mistakes of the past, with too much hype, over-promising and under-delivering in how we use 4D bioprinting and cyborganics terminology. What excites me the most is these novel technologies are starting to merge with the potential to bridge the gap between science fiction and reality. This emerging industry is gaining momentum at a speed that will soon ignite a paradigm shift in disease management and healthcare innovation [1].

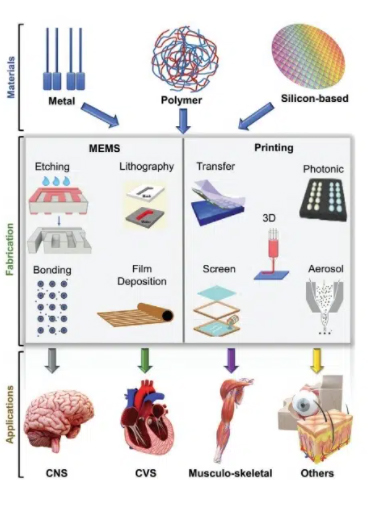

We need to focus on the futuristic innovations and why we need advanced electric, magnetic, acoustic, two-photon, and volumetric technologies merged with cyborganic, electroconductive, magnetic-responsive, biosensing, self-assembly, synthetic biology, and biorobotic biomaterials. With 4D bioprinting technologies, we can catch up to other innovations and create realistic, complex, fully functional high throughput tissues in the fourth dimension, cyborg tissues, human-machine interfacing technologies, animal testing alternatives, bioartificial organs, and futuristic medical devices. As a result of my passion for this sector, I completed a deep dive into all of the scientific literature and start-ups (with the help of some tweets and LinkedIn network connections) to determine the realistic potential of 4D bioprinting & cyborganic biomaterials.

My understanding of the potential surrounding these 4D technologies stems from being fortunate to have had two of the best mentors during my career: a world-leading expert of mechanobiology and founder of the biological engineering department at Massachusetts Institute of Technology in 1998 (Prof. R. Kamm) and my former Ph.D. supervisor at Imperial College London who is an expert in biomechanics (Prof. P. Weinberg). My time under these supervisors and mentors at Imperial College or MIT alongside a former start-up on the hardware side of the 3D bioprinting industry paved the way for me as an entrepreneur to understand the full potential of the merger between 4D bioprinting and cyborganics for futuristic healthcare innovations between man and machine. I would have only dreamed about the prospect of these technologies in my youth when obsessed with science fiction, fantasy novels, superhero comics, or Irish and Greek mythological characters and stories. Will one of the subsequent unicorn start-ups in deep technology emerge from 4D biofabrication technologies, based upon its potential for multiple industries such as regenerative medicine, human-machine interfacing, bioartificial organs, space, defense, synthetic biology, and future medical devices? Only time will tell, but this is a fascinating and futuristic field, and it’s already blurring the lines between science fiction and reality.

What is 4D bioprinting?

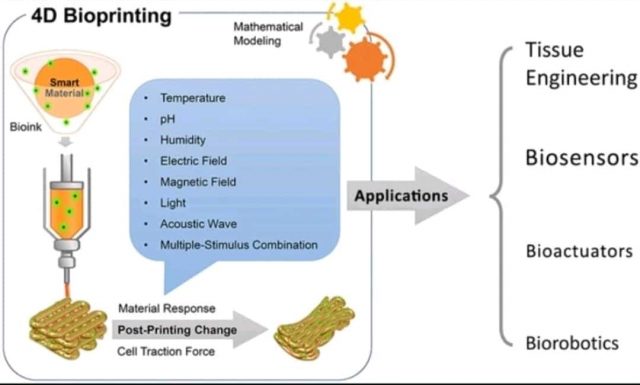

So what is 4D Bioprinting? At present, when you 3D bioprint cells and hydrogels to try and create a bodily tissue or organ, it remains in that static form and does not have any real added value or complexity like what we see in the human body. I won’t reiterate the limitations of what happens when cells in gels experience the shear stress of extrusion processes and cannot form organs. The fourth dimension is when you biofabricate a tissue with advanced electric, magnetic, light, or acoustic technologies, with the resulting tissue not being static but dynamic [2]. It can change conformation and possess human organs’ biomechanical and stimuli-responsive characteristics [2]. The use of cyborganic materials in the fourth dimension provides them with additional functionality that transforms them into potential bioartificial tissues. The fourth dimension provides a much-needed solution to create tissues and organs that fully mimic the physiological environment, including the biomechanics or mechanobiology of tissue and organs, for complete applications in regenerative medicine.

This can never happen with just 3D bioprinting. These new cyborganic properties present a massive potential for creating human-machine interfacing medical devices with the ability to monitor, diagnose and treat disease. The term 4D Printing itself was first introduced by MIT’s Self-Assembly Lab, where external stimuli of light, heat, electricity or magnetic field changed the object in 3D [3]. These new technologies can overcome many limitations of 3D printing, so it was only natural that it also became a new field under regenerative medicine and tissue engineering markets. In the fourth dimension, the use of electric and magnetic field manipulation biofabrication and smart electroconductive, biosensing, biorobotic, or self-assembling material technologies allows the tissue to take on the true dynamic nature of a tissue or organ found in the body.

Xenobots show us a glimpse of what’s possible by taking advantage of the native intelligence of cellular collectivesProf. Michael Levin, Vannevar Bush Distinguished Professor, Director of Allen Discovery Center at Tufts University and Tufts Center for Regenerative and Developmental Biology

One of the most recent transformative innovations released was a surgical robot that can respond to pH and stimuli with the potential to target and kill cancer [4]. Then later this year, the Wyss institute UVM, and Tufts University released their information on A.I.-designed Xenobots [5] with an ability to self-replicate. The work carried out on Xenobiotics by Prof. Michael Levin and others were first reported in a paper published in 2018 and featured by the New York Times in 2020 [6] by the same center at Tufts, as living robots that could swim and gather cells together like Pac-Man; now, they can even self-replicate. Prof. Levin further explains: “Xenobots show us a glimpse of what’s possible by taking advantage of the native intelligence of cellular collectives: instead of micromanaging the construction bottom-up, AI offers the possibility of guided self-assembly: providing stimuli to cells to achieve structure and function that would be too complex to try to engineer directly.”

This research demonstrates the huge potential of what can be achieved within the fourth dimension of self-replicating biorobots. I could never have dreamed of synthetic lifeforms designed by computers to carry out desired functions and build biological tissues. Are they robots or lifeforms? Imagine what can happen next when technologies are merged in the fourth dimension.

Free from hardware

One of the beauties of this 4D bioprinting industry is that hardware is needed at times but not always essential unless it has an added advantage to manipulate the electrical or magnetic fields or other properties of the cellular environment or biomaterials. Smart materials can take on an entire physiological structure without the need for hardware, except for making multicellular layered structures with these biomaterials [2]. In the future, could we have 4D biofabricated bioartificial organs in the body that run on artificial intelligence with decentralized blockchain technology? Could they be connected to a metaverse with the ability to monitor, diagnose, and treat diseases?

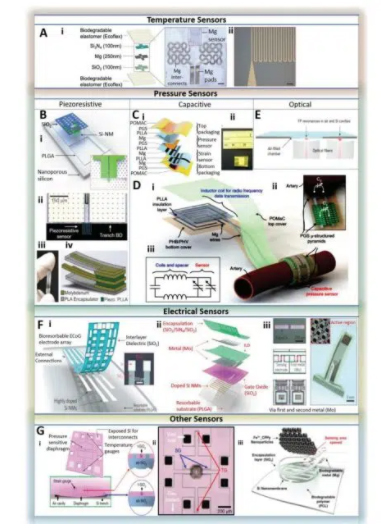

Progress in this sector of 4D Bioprinting and cyborganic biomaterials is creating a shift from world engineering to human engineering to a point where there will be a fine line between humans and machines [1]. The era of cyborg science is evoking a lot of attention at the moment [1]. When we read about other companies within this realm of futuristic innovation such as Elon Musk’s Neuralink, we can get an idea of how 4D bioprinting and cyborganic biomaterials can do much more for this type of human-machine interfacing with future advantages for minimally invasive technologies or biodegradable biosensors. In a 2021 article, Prof. Ashammakhi even detailed the potential of 4D biomaterials that act as biodegradable sensors [7]. The article [7] demonstrates the future potential of this innovative 4D sector, which can drastically improve devices such as neural implants, making them as accurate and reliable as commercially available non-degradable materials. More research is required, but it does demonstrate the potential of these four-dimensional technologies.

Recent [4] advances in 4D bioprinting and biomaterials can not only enhance the industry of regenerative medicine but create novel, minimally invasive, human-machine interfacing technologies that can act as futuristic medical devices. One such device I read about this year is a smartwatch [8] with a sensor biomaterial embedded within the technology to make a lab in a watch. Imagine wearing a smartwatch embedded with a 4D biofabricated disease biomarker sensing technology. The ability to detect changes in pH or inflammation is the start. Still, we could go one step further with technologies like those patented in DTU Denmark by co-founding CTO of the first 4D bioprinting company in the Netherlands, Ourobionics B.V., Associate Professor Alireza Doltashahi-Pirouz. Alireza’s Caregum technology [9] has multiple capabilities including pH responsiveness, thermo-responsiveness, electrically conductive, self-healing, 3D printable with an ability to detect biomarkers of diseases such as Parkinson’s, Alzheimer’s, or Cancer.

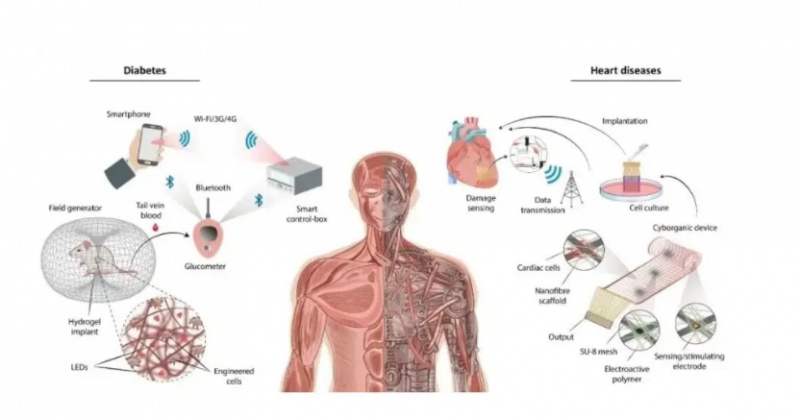

Dr. Doltashahi has identified the value in these technologies for much more than the regenerative medicine and human-machine interface industries with Ourobionics. In his scientific article “The Promise of Cyborganic Beings”, he described how living flesh, hacked beyond known biological borders, and sophisticated types of machinery made by humans, are currently being united to address some of the impending challenges in medicine. In the article, Alireza and others discuss imagining a world of biological systems created from smart biomaterials with the capacity to operate like smart machines to regulate insulin, cardiac patches to release biological factors on-demand or mend broken hearts.

“4D printable soft robotic systems hold one of the keys for expanding human longevity and assuring healthy living again,” explains Associate Professor Alireza Dolatshahi-Pirouz. “They can do this by enabling a perfect merger between man and machine to control our health down to the nanoscale details. They are simultaneously useful for monitoring in vivo tissue models and can thus accelerate the notoriously slow drug discovery process”

4D printable soft robotic systems hold one of the keys for expanding human longevityAlireza Dolatshahi-Pirouz, Associate Professor, Biologically Inspired Material Engineering, DTU Denmark; Co-Founder of Ourobionics (Chief Technology Officer) and Cybosense.

Alireza co-founded Ourobionics to demonstrate that the gap between real-world and science fiction is slowly being bridged by multiplexing innovative technologies in regenerative medicine and human-machine interfacing. The innovation behind many of his technologies goes one step further than these industries, so I am working with his BioEngine team at DTU Denmark to co-found and build his second 4D technology start-up that is currently in stealth mode – Cybosense. Cybosense utilizes the patented Caregum technological advances for novel solutions to multiple other sectors including space, defense, robotics, electronics, equipment, industrial sites, architecture, textiles, metaverse, and VR/AR. These sectors fit under the more comprehensive 4D printing industry for other industrial applications. A 2020 report by EY highlights that smart sensor technologies are the main drivers of industry 4.0, so I anticipate great success for Cybosense and their te4D biomaterials [10].

Making 4D work

Ourobionics are currently exploring ways to combine their advanced technologies and novel technologies in a partnership with a two-time CES award-winning, and 2020 MIT GSW award-winning bioenzymatic fuel company BeFC. BeFC is pioneering an industry with bioenzymatic and biosensing technologies with an additional utility in the 4D bioprinting industry. A collaboration that started following some inspirational synergistic conversations from being selected as Deep Technology Pioneers of 2021 by Hello Tomorrow. Together they are considering novel approaches to the use of 4D Bioprinting and Cyborganics with BioEnzymatic technologies for the new generation of minimally invasive, self-powered, human-machine interfaces. Imagine what you can achieve with self-powered minimally invasive implantable devices.

[Bioenzymatic Fuel Cells] biofuel cells are imitating human energy generationDr. Marie Berthuel, Product Manager and Co-founder of BeFC

“In close relation, there are existing smart electroconductive materials functionalized with enzymes from BeFC – Bioenzymatic Fuel Cells, which enable the transformation of abundant biofuels like glucose and oxygen into an electrical current through biocatalysis. In some ways, these biofuel cells are imitating human energy generation. Biofuel cells from BeFC use bio-inspired materials and act as an enabling technology for the use of 4D-biofabricated safe products,” explains Dr. Marie Berthuel, Product Manager and Co-founder of BeFC.

“Furthermore, there is great alignment with other bioinspired or biosourced solutions such as printed organic biofuel cells from the likes of the startup BeFC,” adds Dr. Jules Hammond, CEO and Co-founder of BeFC

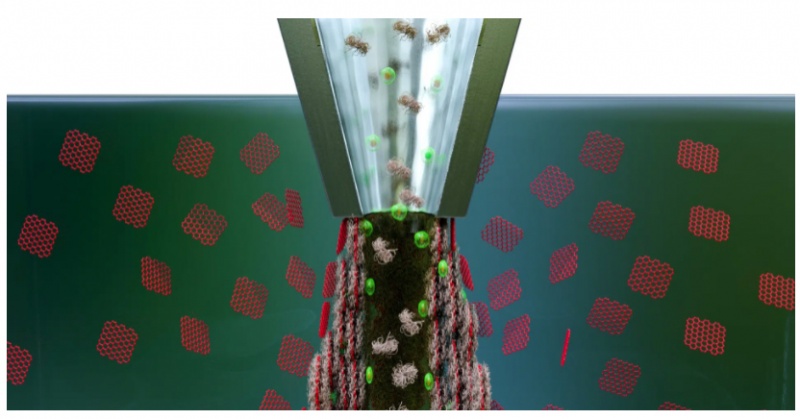

Similarly, the founding Chief Innovation Officer of Ourobionics, Prof. Alvaro Mata, has developed genuinely transformative biomaterial technologies that have huge potential for the fourth dimension. His decades of research into biological assembling technologies offer an opportunity to push the boundaries of biofabrication [11]. “Once you bioprint them—he explains—they can self-assemble to form vessel-like structures, which truly represent what I believe to be the fourth dimension”. His technologies can be used to solve some of the limitations in tissue engineering by enhancing scalability, reproducibility, vascularization, and biomimicry [11]. The power of Alvaro’s self-assembling biomaterial technologies could have substantial transformative value for not only the creation of vessels but to solve many other diseases, including spinal cord injuries or the treatment of neural disorders. Ourobionics are currently exploring the untapped potential utility of Prof. Mata’s 4D biomaterial technologies similar to Dr. Doltashahi’s technologies for regenerative medicine, human-machine interfacing, and medical devices. The potential of the self-assembling biomaterial technologies invented by Prof. Mata can best be described in a separate study, where researchers from North Western University used a type of 4D self-assembling gel injected into the spinal cord of paralyzed mice to stimulate nerve regeneration. Within four weeks, the mice were able to walk again [12].

Wu Y, Okesola BO, Xu J, Korotkin I, Berado A, Corridori I, Pellerej di Brocchetti FL, Kanczler J, Feng J, Li W, Shi Y, Nerukh D, Farafonov V, Wang Y, Titirici MM, Karabasov S, Oreffo ROC, Rodriguez-Cabellor JC, Vozzi G, Azevedo HS, Pugno NM, Bailey CG, Wang W, Mata A (2020). Disordered protein-graphene oxide co-assembly and supramolecular biofabrication of functional fluidic devices. Nature Communications 11, 1182, 10.1038/s41467-020-14716-z

Wu Y, Okesola BO, Xu J, Korotkin I, Berado A, Corridori I, Pellerej di Brocchetti FL, Kanczler J, Feng J, Li W, Shi Y, Nerukh D, Farafonov V, Wang Y, Titirici MM, Karabasov S, Oreffo ROC, Rodriguez-Cabellor JC, Vozzi G, Azevedo HS, Pugno NM, Bailey CG, Wang W, Mata A (2020). Disordered protein-graphene oxide co-assembly and supramolecular biofabrication of functional fluidic devices. Nature Communications 11, 1182, 10.1038/s41467-020-14716-z

This is why Ourobionics plan to complete future research and development on combining their advanced electric field, magnetic field, and microfluidic biofabrication technologies of their soon-to-be-released Chimera platform with the co-founders’ cyborganic and self-assembling biomaterials. The novel multiplexing of technologies will allow for next gen innovations such as a minimally invasive 4D induced pluripotent stem cell cyborganic optogenetic neural stimulation and regeneration device connected to a biofabricated skin sensor.

The co-founders of Ourobionics B.V., Prof. Alvaro Mata and Associate Prof. Alireza are true pioneers in this new emerging industry of 4D Bioprinting, regenerative medicine, and potential use for human-machine interfacing. Ourobionics is the first 4D bioprinting company in the Netherlands and is currently seeking co-investors whilst raising for a seed round. The team aspires to transform regenerative medicine and human-machine interfacing and empower other researchers with novel applications. Still, it can become a leader in Europe, in a market dominated by North America [13].

In a chapter of the book published by Dr. Norbert Radacsi in 2020, “Fabrication of 3D and 4D polymer micro-and nanostructures based on electrospinning” [14], he demonstrates the power of electric field manipulation technologies for 4D bioprinting. The article highlights the potential of technologies similar to those from the Ourobionics Chimera system (3D Bioelectrospraying, Electrohydrodynamic Jetting of Cells, and Cell Electrospinning) and their massive stand-alone potential for 4D bioprinting applications. It even allows for 4D bioprinting to be explored in nanoscale with speeds up to 10X faster than standard extrusion bioprinting. 4D electric field technologies overcome the viability, fabrication speed, and resolution of traditional 3D technology. The full limitations of these emerging technologies have to be thoroughly evaluated over time. Still, we can only begin to imagine what the future holds based upon decades of published evidence demonstrating transformational speeds, high cell viability (90%), nanoscale resolution (50nm), and cells maintaining pluripotent and metabolic characteristics with no DNA damage.

(There is) life in 4D

In 2021 the company 4D Biomaterials, founded in 2018 in the UK, raised 2 million USD in seed funding for bioresorbable biomaterials to be used in medical devices [15]. One of the original 3D bioprinting companies, Poietis, has released news on their work within the scope of 4D bioprinting using their 4D laser-assisted technologies that could replicate dynamic remodeling of fibroblasts [16]. 4D Biomaterials also partnered with BMF to make microscale bioresorbable polymers in medical devices [17]. The industry is in its infancy, but the potential for realistic future medical devices, cyborganic tissues, and bioartificial organs has endless potential. In addition, one of the top emerging startups of 2021, Lattice Medical, is a 4D bioprinting company utilizing bioresorbable materials to improve the use of orthodox implants such as titanium or silicone [18]. The use of 4D bioresorbable implants prevents the need for continuous follow-ups. Lattice Medical guided adipose reconstruction solutions for breast regeneration can overcome the traditional disadvantages of surgery and implants, such as rejection and infection.

NanoRegMed Ltd is one of the earliest 4D biomaterial companies in the industry and has been active for many years utilizing novel graphene biomaterials. The company developed two families of biomaterial-based on functional graphene oxide (FGO) copolymer nanocomposite. The materials have trade names Hastalex and BionHastalex. The former is non-biodegradable, ideal for cardiovascular application and the latter is biodegradable for tissue engineering application. I had the pleasure of working with them years ago on their novel graphene-based biomaterial that has since then been implemented for many sectors of tissue engineering and the regenerative medicine industry. Ecoatoms is another company in this sector that has recently been accepted into a NASA program that will use technologies for commercial suborbital flight tests [19]. Their technology incorporates biomaterial and smart polymer biosensor technologies for medical devices, pharmaceutical, and defense purposes. Biofabics Biomaterials is another start-up whose novel 4D biomaterials have natural self-healing properties and enhance cellular regeneration [18]. I am sure that there are many more young emerging startups in the sector. The industry is moving so rapidly that it is hard to keep up.

Similar to when the 3D bioprinting industry started, companies were in pre-seed and seed investment stages. Back then, 3D bioprinting was at its inception point identical to the stage of the 4D bioprinting industry now. Interestingly, many of the companies that are dominating the 3D bioprinting industry are looking towards future applications within the 4D bioprinting domain. I have noticed from my interactions with my network when writing this article that there is massive interest from the community in terms of working with these new biofabrication technologies and biomaterials and taking their own innovative nano/biomaterials out of the lab and into the industry.

The Evolution Revolution will be GeneticisedAthamanatha Kitsune (Daniel Davies), CEO/Founder, Vulpine Designs

Bioastra Technologies Inc is another highly innovative company with smart programmable biomaterials and mechatronics that can be used for healthcare applications such as medical devices, wearables, and soft robotics. The CEO recently explained to me what 5D biomaterials meant from her perspective. It is when the biomaterials are reused, degraded, or recycled. So I wonder how much further it will go over time. Is this concept still technically part of the fourth dimension? The materials that respond to pH can be used to release genetic content. At present, Vulpine Designs Ltd is working with Ourobionics on using their novel software and Cellinator/Geneticiser prototype technologies for future genetically engineered 4D biofabricated gene-editing vector technology and applications.

“We are very pleased to team up with Ourobionics to develop applications of our systems and concepts in 4D cellular bioprinting,” Athamanatha Kitsune (Daniel Davies), CEO/Founder, Vulpine Designs Ltd tells us. “But that’s just the start. Gene editing that you can rely on and consider to be as routine as a vaccine, as easy as home 3D printing and as versatile as Lego bricks, will in the coming years begin to disrupt many industries, from healthcare to farming, from cosmetics to space travel. The need for traditional drugs will be decimated. The potential in nature’s source code is utterly vast, and we are here to provide the open-source tools and support to unlock it and enable true freedom of form. The Evolution Revolution will be Geneticised.”

One of the novel aspects of Ourobionics technologies is the ability to reach 50nm resolution and encapsulate genes, enzymes, and proteins, making it highly useful for synthetic biology. This combined utility in 4D Bioprinting could have colossal potential to transform the industry of synthetic biology valued at 32.4 billion USD. Synthetic Biology is already changing Biopharma, carbon recycling, textiles, cosmetics, and food20. The Bill Gates-backed synthetic biology company Ginko Bioworks went public this year in a USD 15 billion SPAC [21] so imagine what the future holds for 4D bioprinting of genetic content.

A new way to cure

This new industry of 4D biofabrication can impact biorobotic surgery and synthetic biology and detect diseases at earlier stages, enhance treatments, and improve the patients’ quality of life. Couple this with biofabricated tissue regeneration devices or bioartificial organs, and we are one step close to realistic regenerative medicine and human-machine interfacing. Biofabrication of a complete organ for transplant is still quite a distance from reality. Advances in the genetic engineering of pig organs into humans are outpacing the current research in slow technology. The emergence of the 4D bioprinting industry paves the way for something new: tissues with embedded sensors, electronics, or nanotherapeutics to monitor, treat and cure diseases.

One [5] of the best scientific review articles I suggest for those with a strong interest in these new technologies is drafted by an expert in the field, Prof. Nureddin Ashammakhi. I was fortunate to come across his work during the COVID lockdown. I introduced him to the world of what Ourobionics was building with the co-founders at Ourobionics, and things have gone from strength to strength based upon our interactions over time. To summarize his review article on the technology behind this new industry, “4D bioprinting allows us to obtain the ability to make dynamic physiologically relevant tissue constructs [2]. These tissues can undergo morphological changes and can be used for bioactuation, biorobotics, and biosensing. The use of three-dimensional bioprinting has allowed for the creation of tissues with automated control. Still, the currently biofabricated constructs have limitations, and one big one is they never mimic the dynamic nature, which is an essential process for tissue regeneration in the body [2].

4D bioprinting is moving implants to another level to match body dynamicity and enable the development of more effective therapeutics in the futureProfessor Nureddin Ashammakhi, Institue for Quantitative Health Sciences and Engineering, Department of Biomedical Engineering, Michigan State University

Prof. Nureddin Ashammakhi defines 4D bioprinting as the 3D printing of cell materials with the ability to respond to external stimuli or local factors, stimulants, and triggers [2]. So how do we define stimuli-responsive well in his detailed review? Any 4D biomaterial undergoes conformational in response to changes in temperature, pH, humidity, electricity, magnetic field, light, or acoustics [2]. It coincides nicely with the emergence of advanced biofabrication technologies that make use of all of these types of technologies to go beyond extrusion bioprinting. Temperature responsive biomaterials have a robust utility for multi-material Bioprinting [2]. The materials that respond to changes in pH can be used to release drug compounds, biomolecules, or genetic content 2 through future genetically engineered 4D vector technology such as that which Vulpine Designs Ltd has disclosed to me.

“4D bioprinting is moving implants to another level to match body dynamicity and enable the development of more effective therapeutics in the future. Such 4D engineered therapeutics will live, function, and respond to local and remote stimulation, while in the body,” explains Professor Nureddin Ashammakhi, Institue for Quantitative Health Sciences and Engineering, Department of Biomedical Engineering, Michigan State University.

Sparking it up

Electro-responsive hydrogels are of particular interest to me based on my close to decade-long obsession with building machines that merged the electric field with bioprinting and biomaterials. My experimental work at imperial college alongside other engineers until 2016 led to us inventing prototypes of technologies for 3D cell electrospinning, 3D electrohydrodynamic jetting of cells, and 3D bioelectrospraying with standard extrusion bioprinting.

The original static technologies first invented by the Ourobionics founding CSO Prof. Jayasinghe and put into the third dimension by my prototyping with others could allow us to create tissues and organs with no cell damage or deformation and nanoscale encapsulation. Prof. Jayasinghes technologies have been featured in over 150 publications and listed emerging technologies for 2021 [22]. These electro-responsive materials have already been used for biomedical applications such as drug delivery in an on/off fashion of low electrical voltage, engineering of tissues with a need for electro-responsive properties, and soft actuators within the body [2]. Imagine what could be achieved for self-powered bioelectronics in the body and even interdigitated supercapacitors (it has been partially completed) [2].

In parallel to the electric field responsive materials, the magnetic field can be used for the responsive release of drug compounds [2]. It can use the magnetic field for self-assembly and self-healing properties, regenerating parts of the body once implanted. The use of these magnetic field-responsive technologies has proven to be successful for future cell therapy applications with mesenchymal and embryonic stem cells to regenerate parts of the body that have been damaged potentially [2]. Both of these technologies are not only invented by co-founders of Ourobionics but also complement their electric and magnetic field-based hardware biofabrication technologies. Imagine encoding these into your genome – the Ourobionics and Vulpine Designs collaboration could make that happen.

Light responsive materials are desirable for the 4D bioprinting industry and align with the release of volumetric technologies of Xolo and Readily 3D or two-photon technologies of Cellink/Nanoscribe GmbH (BICO)’s new machine, the Quantum X Bio. These light-based biomaterials were first used to change the color of technologies [2]. Still, photo-responsive hydrogels could be used to direct stem cell differentiation and fate in the biomechanical environment. These photo-responsive properties can be used to induce photo-degradation which is helpful to mimic the dynamic nature of the ECM in the body [2]. Acoustic-responsive materials would be of interest to Mimix biotherapeutics but partially for future Ourobionics R&D into newer modules. Acoustic responsive biomaterials have superior abilities for drug release from hydrogels and can be non-invasive to cells and the environments needed to form tissues and organs. Overall, 4D bioprinting is required to achieve the dynamic processes towards creating hierarchically complex and realistic organs, so we need 4D bioprinting for regenerative medicine2. If we biofabricate shape-memory and cell scaffolds, we can implement minimally invasive delivery of functional tissues and stimulation or regeneration devices [2].

The process of 4D bioprinting allows us to fabricate these technologies in a rapid, controllable manner, accelerating the regenerative potential of what is biofabricated and can qualify for the delivery of cells and genes within narrow spaces of the body for diseases that are difficult to treat. 4D bioprinting can be used to implement biosensors that can monitor the behavior of tissues and organs in the body and monitor cell behavior and function, and at some stage, predict early-stage disease biomarkers or metabolites [2].

One of my favorite sectors of 4D bioprinting is the development of actuators and biorobotics. Imagine a world where we can create biorobotic tissues and tissues to facilitate organ regeneration. There will always be limitations in understanding how cells behave and remain viable with these fantastic technological advantages. So much more is needed at the animal and clinical levels. The latter is not that big of an issue as 3D bioprinting has so many speed and cell viability issues that real high throughput clinical applications are decades away. That being said, 4D bioprinted constructs can take advantage of wireless, communication, data storage, and blockchain technologies, blurring the lines between man and machine within the future metaverse [2]. We need to take the approach of having the 4D bioprinted materials – tissues, organs, and devices – tailored towards products that can solve real-world problems to overcome the scalability, manufacturing, and affordability issues of existing biofabrication technologies. The CEO of Ourobionics, John Zandbergen, has always emphasized the need for future biofabrication and biomanufacturing facilities needed for all sectors for continuous production. To mass produce, cyborganic tissues can be standardized, validated, and cryopreserved with as limited processing steps as possible.

Bioprinting 4.0

In terms [6] of the question ‘is it a genuine emerging industry?’, let me answer this by evaluating multiple market reports. In a report by All The Research, it is estimated that the market size of the 4D printing market has been valued at USD 65.1 million and is expected to grow at a compound annual growth rate (CARG) of 42.1% for the forecast period ending in 2027, reaching a market value of 489.2 million [23]. Even taking into account that these are forecasts based on a large number of variables and estimates, I don’t believe a market has grown this fast since the early years of the 3D printing industry or electric vehicles. According to Research and Markets, the 4D bioprinting market size is much smaller, at a value of 6.7 million USD in 2020 and is expected to reach 36 million USD by 2027 [24].

Even if the 4D Bioprinting industry sector is new and growing, it doesn’t stop new startups from competing with others in the existing markets. These 4D bioprinting companies have a competitive edge to take market share from 3D bioprinting (1 billion USD), tissue engineering (16.3 billion USD), regenerative medicine (115.9 billion USD), and medical devices (657 billion USD). If anything, they have a competitive advantage if their technology has more futuristic potential. Not surprisingly, 4D bioprinting is relatively small similar to all industries in their infancy, but that doesn’t take away from its growth potential in existing markets. It will expand based upon the current level of company formation. If anything, it is a good indicator of a new industry or something that has been captured at its inception point.

According to a market research report published by Global Market Estimates, the smaller 4D bioprinting market is expected to grow independently at a compound annual growth rate of 28.5% from 2020-2026 [13]. There is a growing focus on raising funds for these research activities, allowing the market to grow in the healthcare sector. The use of 4D bioprinting provides the development of smart tissue models, self-repairing tissue, drug delivery issues, and more. The report mentions that the market will be trending in the coming years due to the launch and adoption of 4D bioprinting software [13]. According to the recent reports, it is the fastest rate of development in this market. Dental clinics are expected to grow the fastest based upon an expanded interest in 4D bioprinters for dental research, with North America dominating the market. The report also states that there is an increasing level of investment in 4D biomanufacturing and that there is a shift of interest of consumers from 3D to 4D printing. Still, there are risks, including high production costs, safety hazards of technologies, and strict governmental regulations.

I can imagine a world where many 3D bioprinting companies will be interested in being a part of the field. Many could make the shift to adopting or acquiring more smart biomaterials and other 4D bioprinting technologies. It is also expected that the programmable materials segment of the market will grow at a compound annual growth rate of 23.7% to go from 1 million to 4.4 million USD [13, 23, 24]. Right now, 4D bioprinting is a small industry in comparison to the almost 1 billion USD 3D bioprinting industry, but it did take that sector 5-10 years to get to where we are now. If 4D Bioprinting takes off and takes a market share of regenerative medicine, human-machine interfaces, and medical devices, it could have massive potential for exponential growth. Like most deep technology sectors that take decades to grow. That being said every industry has to start somewhere.

The emergence of the 4D bioprinting industry has begun, with several new startups active in the field. Only time will tell what happens next within this newly emerging field. Will it be as successful or even overtake the existing 3D bioprinting industry? Will the next deep technology unicorn come from this sector? We don’t know, but I still remember talking to those skeptical about 3D bioprinting hardware back in 2015, and the industry went from strength to strength. The emerging technology of 4D bioprinting and cyborganics is highly innovative and inspiring. Still, we need more work and more time to fully evaluate the potential of this industry and not get caught up in just another hype cycle. This time, the claim is not that we can bioprint organs. We are not claiming that we can biofabricate bioartificial organs, therapeutic devices, and human-machine interfaces, blurring the lines between science fiction and reality. My imagination gets over-excited about human-machine interfaces and 4D bioartificial organs as I could only dream of these as a student. Still, it is something I feel pretty passionate about for regenerative medicine.

We need to be realistic and avoid too much hype. In 2021 there is enormous value in technology that can grow the entirely new emerging industry of “Bioprinting 4.0”. The research is climbing towards a peak, and more start-ups are beginning to form within this new industry as it has more substantial potential for developing future regenerative or human-machine interfacing medical devices. Biofabrication may not be destined to become the solution to organ transplants but rather something with even more transformative value for multiple health care sectors. Similar to when the 3D bioprinting industry started to pick up speed in 2015, the technology requires more research, and it is not available to everyone. However, we at Ourobionics and Cybosense want to make sure the advanced electric, magnetic biofabrication technologies and the self-assembling and electroconductive, biosensing 4D biomaterials make it into the hands of all researchers and entrepreneurs at affordable price points. The power is in the research community and the citizen scientist movement and inspires others to make their 4D Bioprinting or future human-machine interface applications.

Time to go Beyond Bioprinting!

References:

1. Orive, G., Taebnia, N. & Dolatshahi-Pirouz, A. A New Era for Cyborg Science Is Emerging: The Promise of Cyborganic Beings. Advanced Healthcare Materials 9, 1901023 (2020).

2. Ashammakhi, N. et al. Advances and Future Perspectives in 4D Bioprinting. Biotechnol J 13, e1800148 (2018).

3. https://slidingmotion.com/4d-printing-a-future-technology/ 4D Printing A future technology.

4. https://newatlas-com.cdn.ampproject.org/c/s/newatlas.com/robotics/microrobot-fish-crab-drug-delivery/?amp=true 3D printed microrobot.

5. https://wyss.harvard.edu/news/team-builds-first-living-robots-that-can-reproduce/ Xenobots: The first living robots that can reproduce.

6. Times, N.Y. Meet the Xenobots, Virtual Creatures Brought to Life. https://www.nytimes.com/2020/04/03/science/xenobots-robots-frogs-xenopus.html (2020).

7. Ashammakhi, N. et al. Biodegradable Implantable Sensors: Materials Design, Fabrication, and Applications. Advanced Functional Materials 31, 2104149 (2021).

8. https://www.oulu.fi/en/projects/tandem-industry-academia-tia-2021-project-development-wearable-lab-watch-optical-sensor-non-invasive Wearbale lab in a watch. (2021).

9. Denmark, D. Caregum: A new soft electronic material for human-machine-interfacing. https://www.dtu.dk/english/news/Nyhed?id=%7B09ABB76D-5431-47A1-9D1D-8FA036403119%7D (2021).

10. EY How Smart Materials Are Driving the Industry Forward. https://www.ey.com/en_ch/industrial-products/how-smart-sensors-are-driving-industry-4-0-forward (2020).

11. Hill, J., Wildman, R. & Mata, A. Exploiting the fundamentals of biological organization for the advancement of biofabrication. Current Opinion in Biotechnology 74, 42-54 (2022).

12. Scientist, N. Paralysed mice walk again after gel is injected into spinal cord. https://www.newscientist.com/article/2297272-paralysed-mice-walk-again-after-gel-is-injected-into-spinal-cord/#:~:text=A%20self%2Dassembling%20gel%20injected,that%20helps%20cells%20to%20grow. (2021).

13. GME Global 4D Printing and Bioprinting Market Report. https://www.globenewswire.com/en/news-release/2020/10/08/2105536/0/en/Global-4D-Bioprinting-4D-Printing-in-Healthcare-Market.html (2020).

14. Radacsi, N. & Nuansing, W. Chapter 7 – Fabrication of 3D and 4D polymer micro- and nanostructures based on electrospinning, in 3D and 4D Printing of Polymer Nanocomposite Materials. (eds. K.K. Sadasivuni, K. Deshmukh & M.A. Almaadeed) 191-229 (Elsevier, 2020).

15. Press, D.B. https://4dbiomaterials.co.uk/4d-biomaterials-completes-1-6m-2-2m-seed-round/ (2021).

16. Douillet, C. et al. From local to global matrix organization by fibroblasts: a 4D laser-assisted bioprinting approach. Biofabrication (2021).

17. Prnewswire https://www.prnewswire.com/news-releases/bmf-and-4d-biomaterials-partner-to-bring-bioresorbable-materials-to-micro-3d-printing-301438952.html (2021).

18. Insights, S. https://www.startus-insights.com/innovators-guide/5-top-emerging-tissue-engineering-startups-impacting-the-biotech-industry/.

19. Space tech selected for sub orbital flight. https://www.nasa.gov/center/armstrong/features/space-tech-for-suborbital-flight.html (2021).

20. synthetic biology is shaking up these 5 industries some of them might surprise you https://synbiobeta.com/synthetic-biology-is-shaking-up-these-5-industries-some-of-them-might-surprise-you/.

21. Ginko Bioworks 15 billion SPAC. https://www.cnbc.com/2021/05/11/bill-gates-backed-ginkgo-bioworks-going-public-in-15-billion-spac-.html.

22. Puertas-Bartolomé, M., Mora-Boza, A. & García-Fernández, L. Emerging Biofabrication Techniques: A Review on Natural Polymers for Biomedical Applications. Polymers (Basel) 13 (2021).

23. 4D Printing market expected to reach 489.2. https://www.digitalengineering247.com/article/global-4d-printing-market-is-expected-to-reach-489.2-million-by-2027#:~:text=The%204D%20Printing%20Market%20size,value%20of%20US%24489.2%20million.

24. 4D Printing Healtcare industry. https://www.businesswire.com/news/home/20210719005581/en/6.7-Million-Worldwide-4D-Printing-in-Healthcare-Industry-to-2027—Featuring-3D-Systems-Cadence-Design-Systems-and-Stratasys-Among-Others—ResearchAndMarkets.com.

25. Rio Tinto Sports Innovation Project- 3D Bioprinted Sensors. https://raunaqbo.se/3d-printed-pressure-sensors.

Avtor: Stephen G. Gray