Researchers at the University of Minnesota have made a ground-breaking advancement in 3D printing for medical purposes – they have used motion-capture technology to 3D print directly onto expanding organs! This technology is usually used in film making to create special effects, but recently, it has been successfully tested for additive manufacturing in the medical sector. Just a few years ago it was unimaginable, but today it can bring important changes to many medical practices, and very soon too – the new method can help diagnose and monitor the lungs of COVID-19 patients.

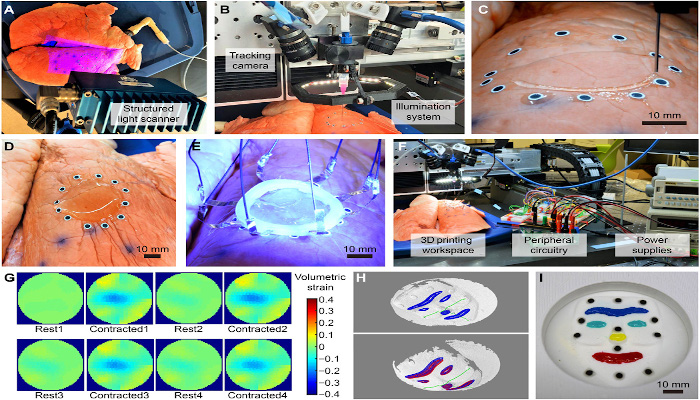

Despite the fact that additive manufacturing can work with a wide variety of materials from plastics and metals to biomaterials, AM has taken longer to have an impact in bioprinting applications that typically focus on live biological surfaces. The reason is that 3D printing directly onto moving soft tissues is very challenging – sensors need to adapt to the organ’s constantly changing parameters, after all, living organs are never still, they continuously expand and contract. But the researchers at UMN developed a new technique that overcomes this obstacle by using dual-cameras to create a toolpath for 3D printing in real time.

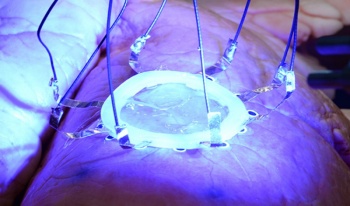

The researchers suggested that the space of deformation of the surface could be “learned” from a dataset of 3D scans. This would allow accurate surface geometry to be recovered in 3D and used to adapt the 3D printing toolpath in real time. For the mission, researchers used motion capture tracking markers — similar to the ones used in the movie industry to create special effects — to help the 3D printer adjust its printing path to the expanding and contracting movements of the organ. To demonstrate their novel sensor and motion capturing technique, the researcher team 3D printed a hydrogel-based EIT (Electrical Impedance Tomography) strain sensor directly onto a breathing lung to monitor its deformation.

The researchers admit that the biocompatibility of the sensors should be further enhanced and the overall precision of the technique improved. Once that is done, this method could open new surgical applications for bioprinting. For example, in clinical cases where injections of biological materials is required, in situ autonomous 3D printing could replace manual operation, to achieve precise spatial control over longer durations.

It is likely that in the near future, this adaptive 3D printing technique will enhance robot-assisted medical treatments with additive manufacturing capabilities, enabling autonomous and direct printing of biological materials on and inside the human body. Professor Michael McAlpine, lead researcher on the project believes, “We are pushing the boundaries of 3D printing in ways we never even imagined years ago. In the future, 3D printing will not be just about printing, but instead be part of a larger autonomous robotic system. This could be important for diseases like COVID-19, where health care providers are at risk when treating patients.”