The U.S. Department of Energy (DOE) has awarded $3 Million to polySpectra and Fortify, along with National Renewable Energy Laboratory, MPI Systems, RePliForm Inc, and Oak Ridge National Laboratory (ORNL). This funding will be used for the development of durable, direct 3D printed tooling that can be used for automotive lightweighting using Cyclic Olefin Resin-based composites. The project is in line with the DOE’s overall goals to decarbonize the U.S. industrial sector, advance clean energy manufacturing and improve America’s economic competitiveness and workforce diversity.

As climate change becomes a bigger concern, decarbonization and clean energy manufacturing are quickly moving past the status of buzzwords to real needs in industry. The DOE, especially through the ORNL has been a forerunner for this, researching the many different ways that technologies, especially additive manufacturing, can be used to make cleaner energy. This latest investment shows their confidence in the technology when it comes to tooling. Namely, they are hoping Fortify, a provider of 3D printers for advanced photopolymer composites, and polySpectra, a supplier of highly durable photopolymer resins will be able to make advancements in the arenas of cost, durability and of course sustainability by combining additive manufacturing with resin-based composites.

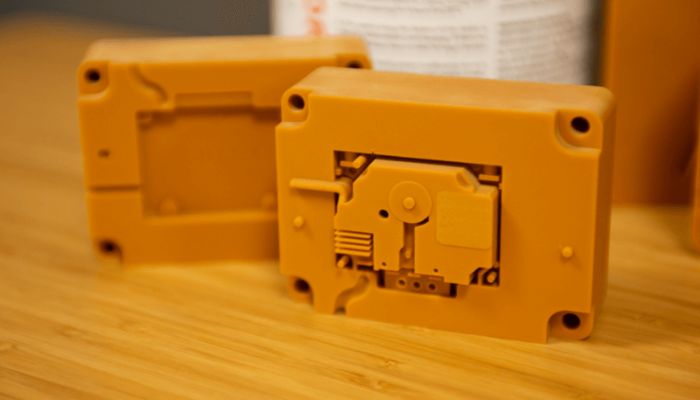

Fortify already has significant experience in the arena of 3D printed tooling. The company combines 3D printed molds with injection molding for robust solutions (photo credits: Fortify)

Raymond Weitekamp, polySpectra founder and principal investigator for the award, expanded, “Olefin-based thermoset composites have been used for many decades in extremely demanding applications such as wind turbine blades and fuel cell components, because they are among the most durable materials on the planet. Under this research grant, we will leverage Nobel-winning chemistry to directly 3D-print these robust composite Cyclic Olefin Resins. The goal of the DOE project is to bring unprecedented materials durability to additive manufacturing, which will provide the industry with immense leverage for the decarbonization and reshoring of the US manufacturing sector.”

The Benefits of 3D Printed Tooling

3D printed tooling has always been one of the major applications for additive manfuacturing, especially when combined with another process like injection molding. This is because, among other benefits, AM allows for more flexibility when designing tools, allowing fewer iterations to be made and saving on materials. And it also tends to be considered to have an advantage in terms of sustainability, as compared to CNC machining, since AM allows for significantly less waste. And these factors have contributed to the DOE’s interest in the technology in order to develop more sustainable manufacturing.

This project aims to develop additive tooling in the automotive industry (photo credits: Volkswagen)

In this specific project, the goal is to further develop additively manufacturing tooling until it is on par with CNC tooling in terms of cost and durability. They will be using AM and lightweight materials to develop what they claim would be a “next generation solution for creating long-lasting inserts for the molding of production volumes of lightweight automotive components from engineering-grade materials, including polymers, composites, and metals.” Ultimately, the work is expected to address the need to develop methods for commercial vehicle part production. Moreover, according to the press release, in terms of sustainability, AM will also help to accelerate improvements in transportation vehicle fuel efficiency as well as help to achieving energy savings and emissions reduction.

An additional aspect of the project, is that they also hope to amplify underrepresented groups in the automotive manufacturing sector. This will be accomplished by helping them to build skills in additive manufacturing and rapid tooling through training and targeted recruitment programs. This way, they will have access to a diverse pool of candidates who will be equipped then to enter the automotive work force. Considering the lack of representation, including people of color and women, in both STEM in general and additive manufacturing as a whole, it is a plan that could ultimately be a real asset for the industry. You can read more about it in the press release HERE.