More than once, British manufacturer Renishaw has proven that additive manufacturing is capable of helping many different industries. From aerospace to healthcare all the way to sports, the company is slowly integrating the technology into a variety of sectors through different applications, and Renishaw has no intention to stop there. The company recently announced that it has extended its partnership with Atherton, the Welsh custom bike manufacturer. Already leveraged by several bicycle companies, Renishaw’s 3D printing technology aims to improve and optimize Atherton’s production process.

Atherton’s primary reason for using Renishaw’s services was to take advantage of the benefits of additive manufacturing, including speed of production, manufacturing techniques, and sustainability. Bryan Austin, sales manager for Renishaw’s additive manufacturing group, explains: “By investing in additive manufacturing processes, Atherton has the design freedom to develop the best parts for its bikes, something that was difficult to achieve using traditional casting methods. Casting using molds does not lend itself to producing the bespoke components that are required for Atherton’s customers. Casting also produces heavier parts because it cannot produce the internal honeycomb structure that allows 3D printed parts to be lighter.”

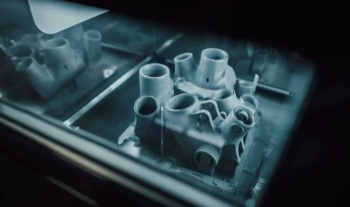

Atherton uses the Renishaw RenAM 500Q 3D printer (Photo credit: Atherton Bikes)

The Advantages of Metal 3D Printing

To 3D print the new custom parts, Atherton decided to make use of the RenAM 500Q 3D printer. Equipped with four lasers and a printing volume of 250x250x350mm, the machine is based on Selective Laser Sintering (SLM) technology and is therefore capable of producing high-quality metal parts. By using this innovative technology, the company was also able to 3D print parts for bicycle frames from titanium. Parts produced with that material are strong and robust, but at the same time quite light. The parts also help to distribute the stresses on the bike over difficult terrain.

Over time, more and more bike manufacturing companies are starting to incorporate various 3D printed parts into their models, making use of the many benefits the technologies have to offer. While Renishaw has been making regular news in this sector, other players, such as Mythos and Kimoa, are also very active. In the future, it will not be surprising to see the number of companies specializing in additive manufacturing and bike production multiply. To find out more about Artherton and its bike models, you can visit the company’s website HERE.

*Crédits photo de couverture : Atherton Bikes